会议酒店:

西安建国饭店 (陕西省西安市新城区互助路2号)

联系人:白经理189 6681 1173 房型:单早双早380元/天

Conference hotel:

Xi 'an Jianguo Hotel (No.2 Huzhu Road, Xincheng District, Xi 'an, Shaanxi Province)

Contacts:Manager Zhu +86-189 6681 1173

Room type:Double room /Twin room: ¥380 Net including breakfas

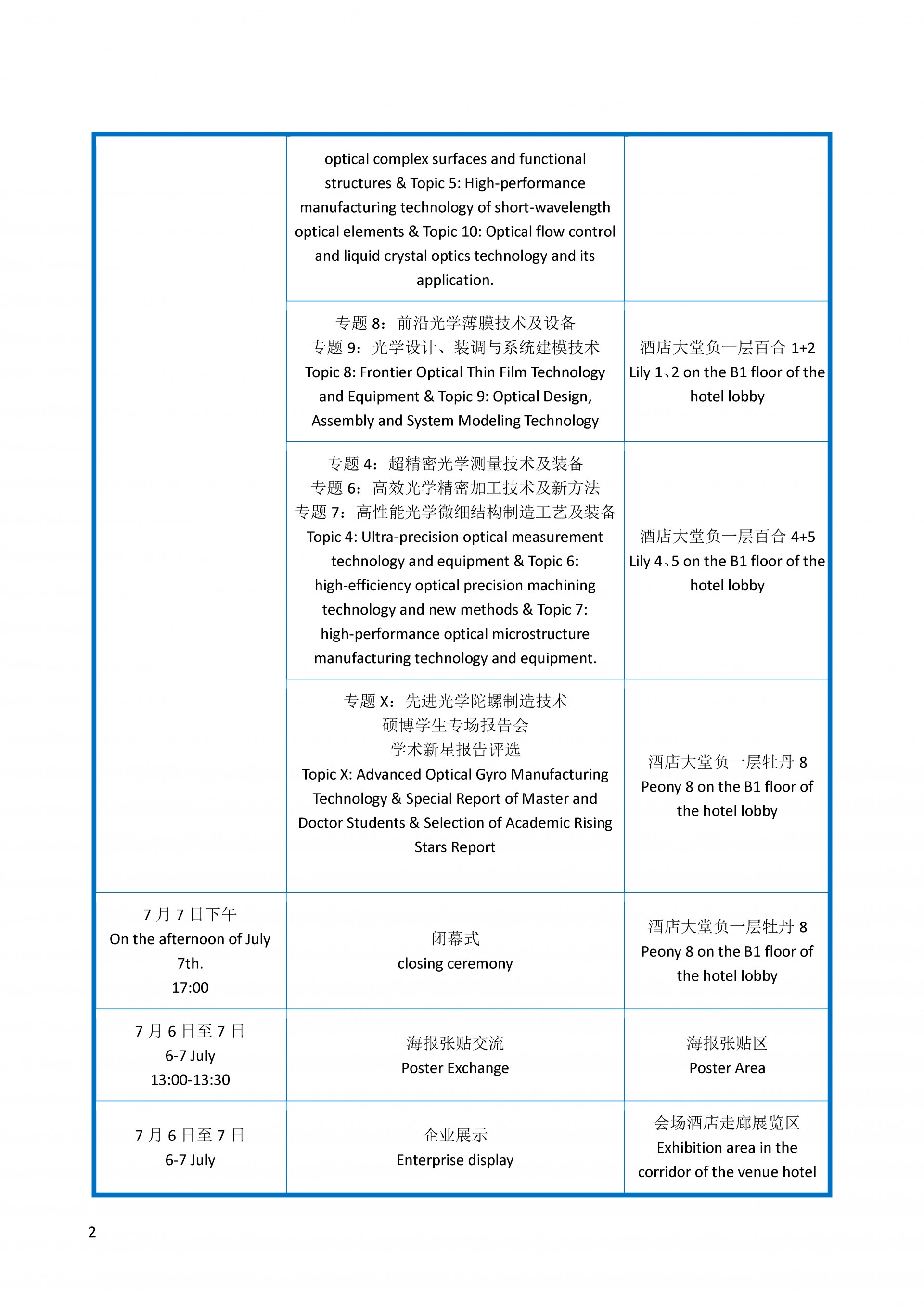

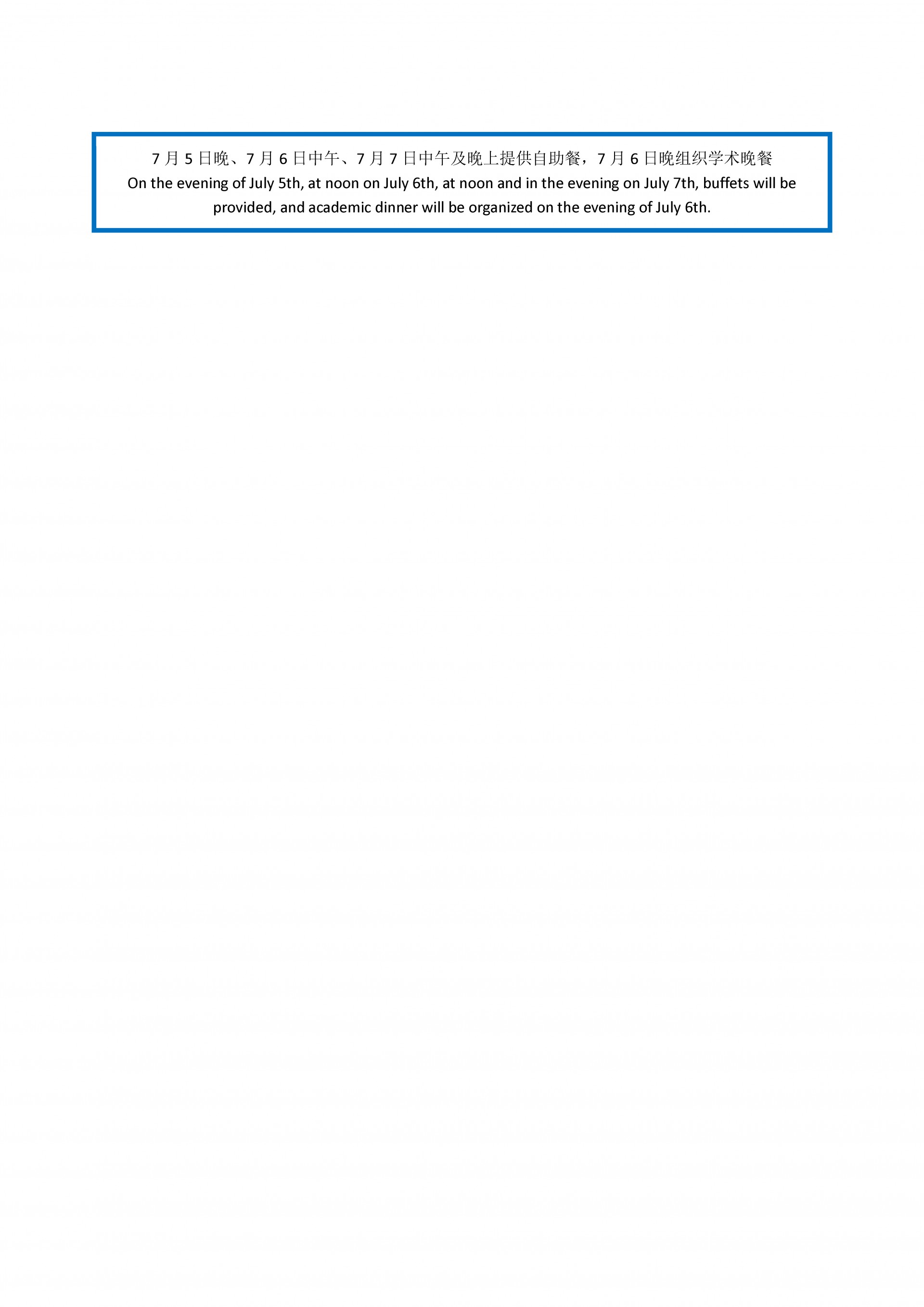

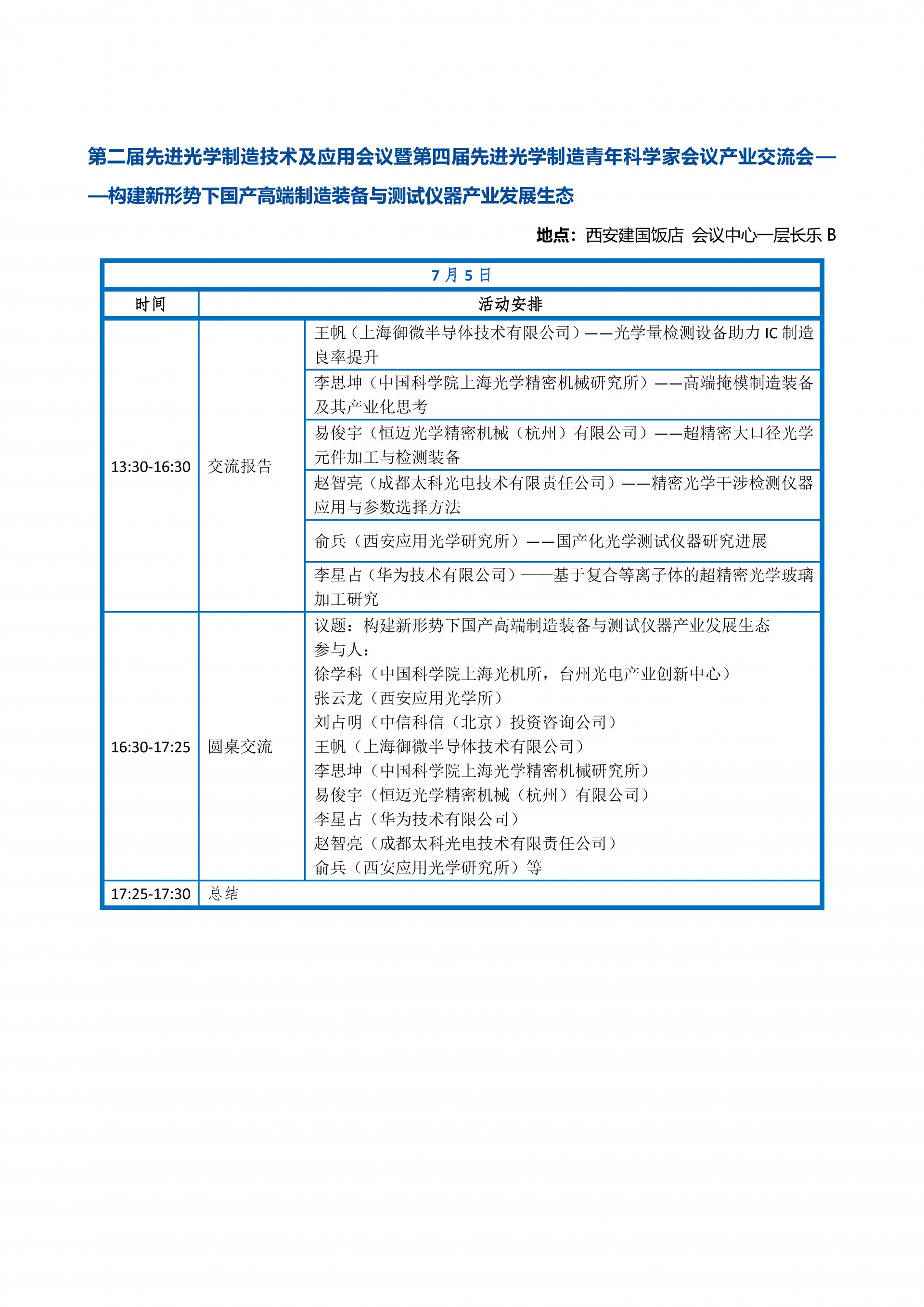

新形势下超精密制造行业已成为全球重要的技术和经济领域之一。目前,欧美、日本、中国等国家和地区仍是高端制造装备和测试仪器生产地。近几年,伴随国内需求的不断提升,国产高端制造装备与测试仪器得到迅速发展,市场规模不断扩大。

中国光学工程学会先进光学制造青年专家委员会于2024年7月5日在西安召开“构建新形势下国产高端制造装备与测试仪器产业发展生态”主题产业交流(https://b2b.csoe.org.cn/meeting/YSAOM2024.html#590_608)。

邀请行业知名企业参加共同探讨超精密制造机遇与挑战。会议诚邀高端制造装备企业、测试仪器企业、半导体企业、手机/车载企业、科研院校、投融资机构等单位人员报名参会交流。

主办单位:

中国光学工程学会(CSOE)

承办单位:

中国光学工程学会先进光学制造青年专家委员会

西安应用光学所

主 席:

徐学科(中国科学院上海光机所,台州光电产业创新中心)

张云龙(西安应用光学所)

共主席:

任明俊(霖鼎光学(上海)有限公司、上海交通大学)

吴易明(西安中科光电精密工程公司、中国科学院西安光学精密机械研究所)

熊 涛(湖北久之洋红外系统股份有限公司)

罗少卿(湖南天创精工科技有限公司)

王 朋(天津津航技术物理研究所)

石 峰(国防科技大学)

沈正祥(同济大学)

戴 博(上海理工大学)

鲁艳军(深圳大学)

参会主体:

高端制造装备生产企业、测试仪器生产企业、半导体企业、手机、汽车企业、科研院校、投融资机构等 ......

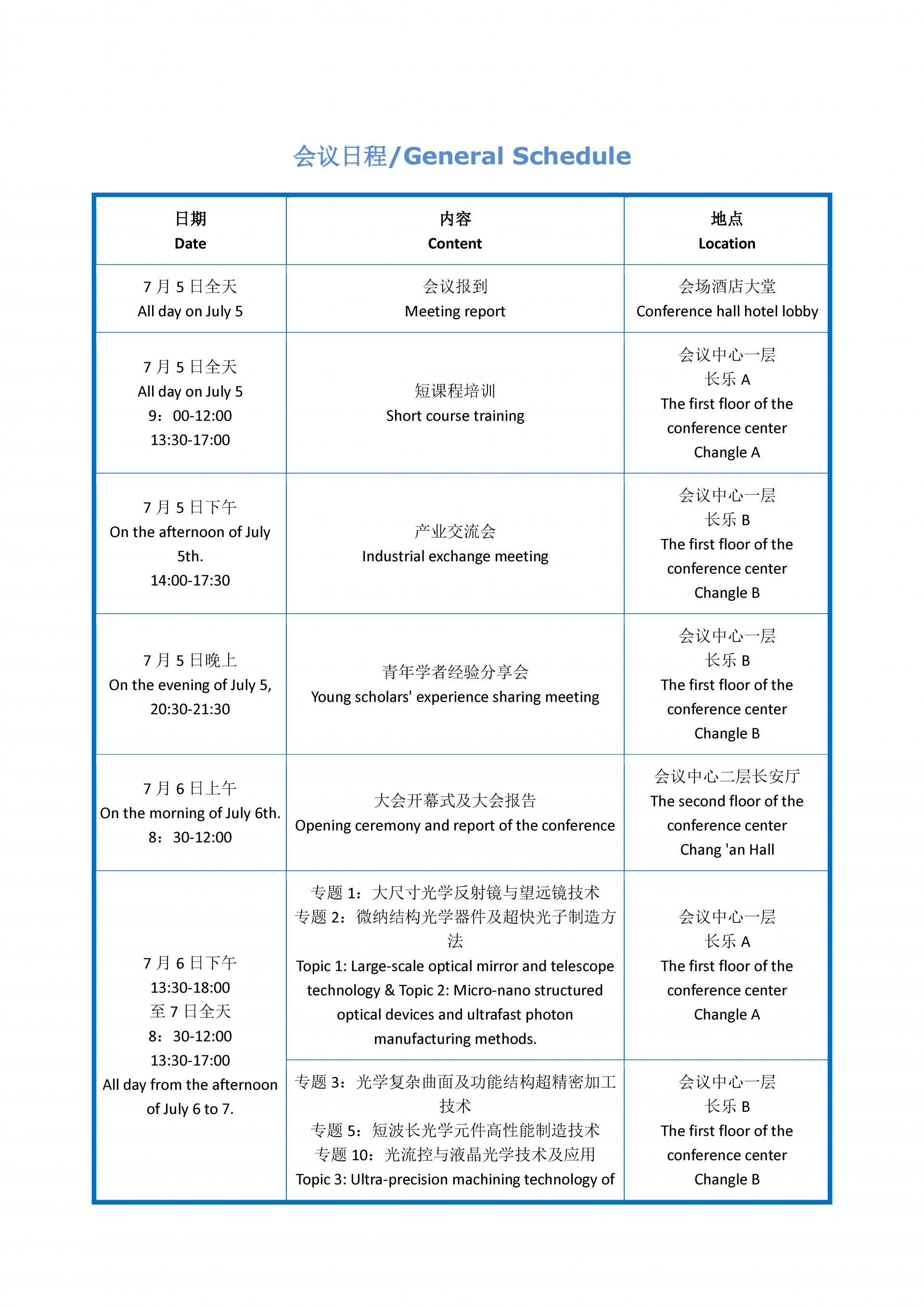

活动日程:地点:西安建国饭店

|

7月5日

|

|

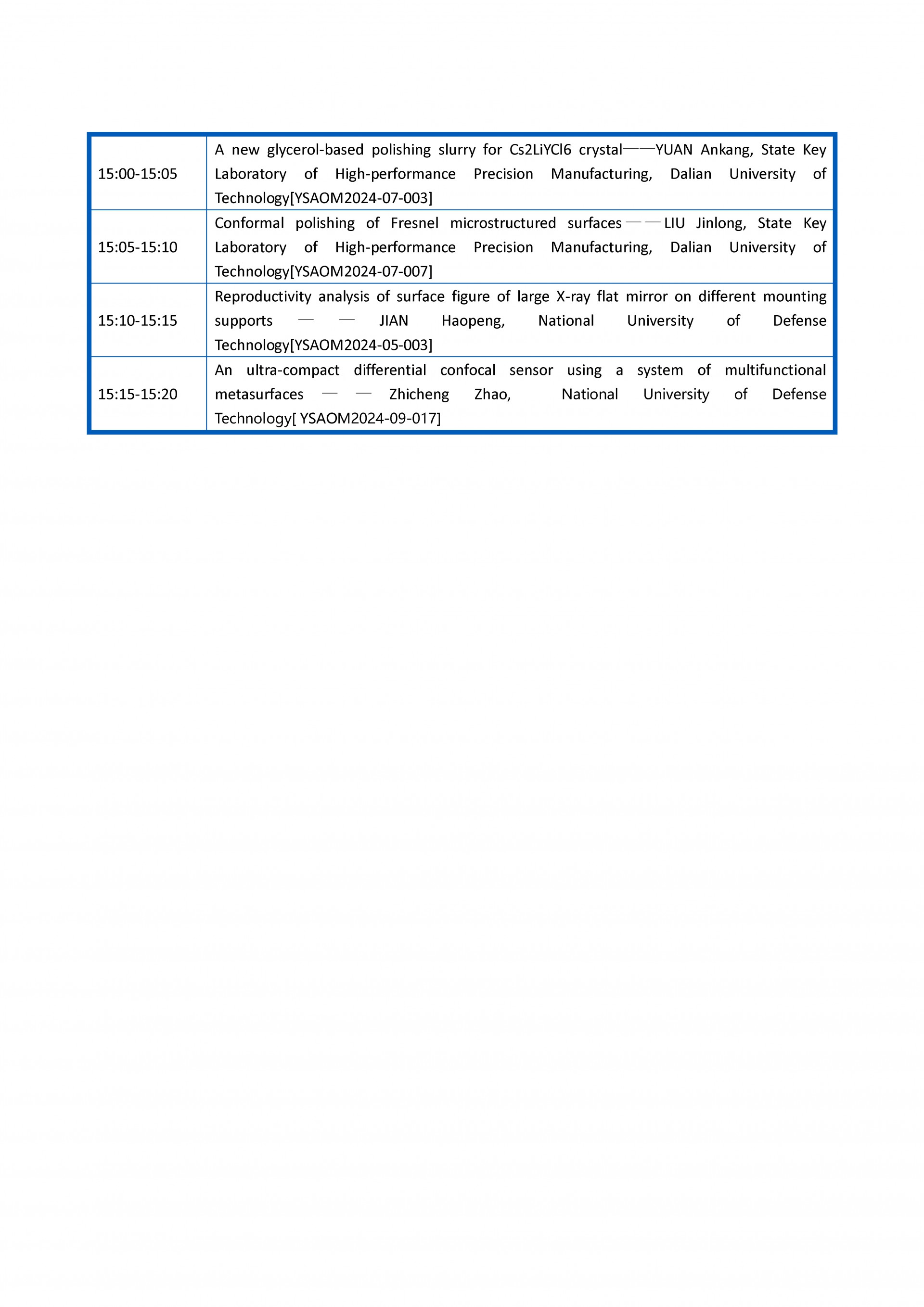

时间

|

活动安排

|

|

13:30-16:30

|

交流报告

|

王帆(上海御微半导体技术有限公司)——光学量检测设备助力IC制造良率提升

|

|

李思坤(中国科学院上海光学精密机械研究所)——高端掩模制造装备及其产业化思考

|

|

易俊宇(恒迈光学精密机械(杭州)有限公司)——超精密大口径光学元件加工与检测装备

|

|

成都太科光电技术有限责任公司——精密光学干涉检测仪器应用与参数选择方法

|

|

西安应用光学研究所——国产化光学测试仪器研究进展

|

|

中图仪器股份有限公司——坐标测量仪器的技术发展

|

|

李星占(华为技术有限公司)——基于复合等离子体的超精密光学玻璃加工研究

|

|

交流讨论

|

|

16:30-17:25

|

圆桌交流

|

议题:构建新形势下国产高端制造装备与测试仪器产业发展生态

参与人:

交流报告人:

嘉宾:刘占明,中信科信(北京)投资咨询公司

|

|

17:25-17:30

|

总结

|

欢迎注册参会!

参会者请务必到以下网址进行会议注册:https://b2b.csoe.org.cn/registration/YSAOM2024LT.html

参会费:100元/人。

同期活动:

第二届先进光学制造技术及应用会议暨第四届先进光学制造青年科学家会议

https://b2b.csoe.org.cn/meeting/YSAOM2024.html

短课程培训:

https://b2b.csoe.org.cn/meeting/YSAOM2024SC.html

活动联系人:

吕子辰(中国光学工程学会)

lvzichen@csoe.org.cn,13810226340

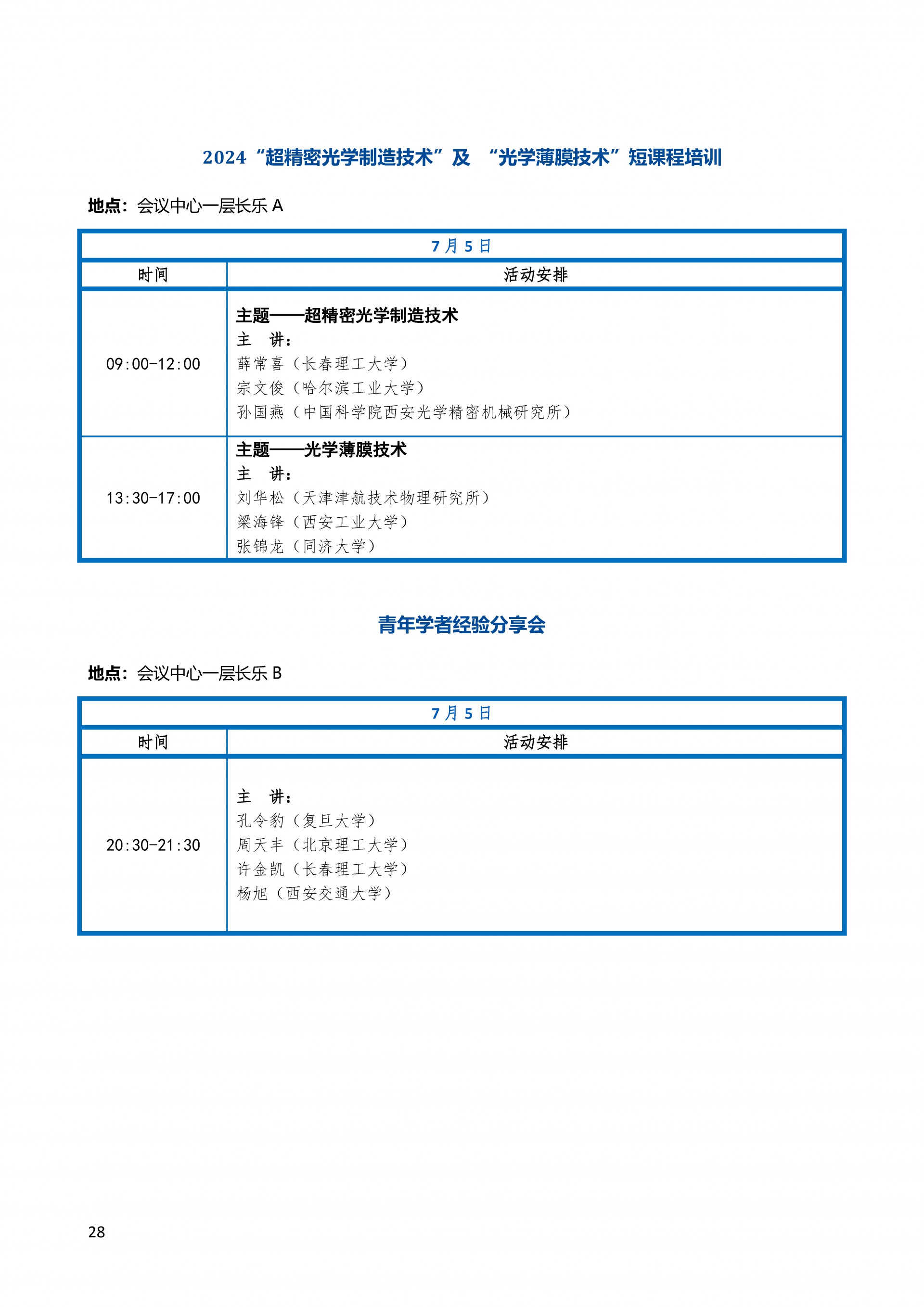

在激光核聚变、大型空间望远镜、航空航天、同步辐射光源为代表的各类光源大科学装置等国家重大光学工程与重大任务的驱动下,对自由曲面/复杂曲面、高面形精度与高表面质量光学元件的需求量日益增加,因此高精度与高效率先进光学制造技术的重要性尤为凸显,其技术创新与应用场景也在飞速发展。本短课程主要介绍高精度光学元件制造的超精密车削、磨削和抛光技术,采用理论技术结合实践应用的方法,由综述先进光学制造技术的研究现状与前沿进展起始,结合难加工光学材料、制造工具、算法仿真与能场辅助等方面介绍多种类型超精密车削、磨削和抛光方法的技术特点、加工机理、参数影响规律、核心关键技术、技术难点与解决方案,并介绍在应用至微纳结构、非球面与自由曲面光学元件制造中的典型案例分析,探讨当前存在的问题和挑战,展望先进光学制造技术发展的前沿趋势,力争培养国家急需的高端光学制造行业的工程人才,为我国成为世界制造强国奠定技术应用基础。

一、培训时间:

2024年7月5日9:00-12:00(8:00-9:00签到)

二、培训地点:

西安建国饭店

三、主办单位:

中国光学工程学会

四、承办单位:

中国光学工程学会先进光学制造青年专家委员会

五、课程形式:

授课式,实例解析

六、课程说明:

学员自带电脑,自带Zemax软件,完成培训发放培训证书

七、讲师介绍:

薛常喜,长春理工大学光学工程学科教授,博士生导师,2011年香港理工大学从事博士后研究工作。主要从事光学设计与衍射光学、光学超精密制造技术及其应用方面的研究工作。现中国光学工程学会先进光学制造青年专家委员会副主任委员,全国光学和光子学标准化技术委员会光学材料和元件分技术委员会委员,中国光学学会光学制造技术专业委员会委员,红外与激光工程等期刊青年编委。现主持国家自然科学基金等国家级、省部级高层次科研项目。在国内外学术刊物发表论文50余篇,多篇论文被Spotlight on Optics和Edtior pick。获吉林省自然科技奖三等奖一项,吉林省自然科学学术成果奖二等奖一项,国防科学技术进步奖三等奖一项,兵器集团科技进步二等奖一项,博士学位论文获吉林省优秀博士学位论文。

宗文俊,哈尔滨工业大学机电工程学院教授、博士生导师,目前为中国生产工程分会精密工程与微纳技术专业委员会委员、中国机械工程学会高级会员、国际纳米制造学会会员、亚洲精密工程与纳米技术协会会员。近20年来,一直从事天然金刚石刀具与微工具制造技术、可见光-红外宽频谱光学超精密车削技术研究,发表学术论文70余篇,编写专著1部。主持并参与了国家自然科学基金、国防基础科研核科学挑战计划与重点、国家重大科技专项、授权国家发明专利近30项。指导博士生获2020年中国机械工程学会上银优秀博士论文铜奖1人次,荣获机械工业联合会技术发明二等奖、国防科技进步三等奖、兵器工业集团科技进步二等奖等科研奖励。

孙国燕,博士,中国科学院西安光机所副研究员,硕士生导师,国防科技大学博士后,主要从事超精密磨削技术与先进光学制造技术研究。入选中国科学院青年创新促进会会员、中国科学院“西部之光”人才计划(优秀),担任中国光学工程学会第一届先进光学制造青年专家委员会委员、西安光机所超精密磨削学科带头人、青促会副组长与女科协理事。主持了国家自然科学基金、陕西省/湖南省自然科学基金、中国博士后基金、中国科学院“西部之光”项目和青促会项目、西安光机所自主部署科研项目等课题,作为项目负责人研制并交付了国家重大任务与先进阿秒激光设施中大口径SiC主次反射镜、红外透镜、高陡度抛物镜、X射线超环面镜等核心光学元件30余项,发表论文20余篇。

八、超精密金刚石车削技术提纲

第一部分 光学超精密车削技术概论

1.1 超精密加工技术概况

1.2 单点金刚石车削工件中心误差辨识

1.3 快/慢刀辅助车削技术

1.4 超精密飞刀切削加工多层次微纳结构

第二部分 难加工材料光学元件的超精密金刚石切削技术介绍

2.1 典型难加工光学材料及其应用

2.2 超声振动金刚石切削技术简介

2.3 超声振动金刚石切削装置的设计

2.4 难加工材料超声振动切削材料去除机理

2.5 光学功能表面超精密制造及其应用

第三部分 超精密切削的特点和加工表面质量影响规律

3.1 超精密切削的特点

3.2 切削参数对加工表面粗糙度的影响

3.3 金刚石刀具晶向和刀刃质量对加工表面粗糙度的影响

3.4 工件材料特性对加工表面粗糙度的影响

第四部分 复杂光学曲面的超精密磨削技术

4.1 光学元件超精密磨削技术概况

4.2高精度磨削的面形精度提升技术

4.3低损伤磨削的基础理论模型与抑制方法

4.4 超声振动与复杂结构的超精密磨削技术

第五部分 复杂光学曲面的超精密抛光技术

4.1 光学元件超精密抛光技术概况

4.2 高精度控形抛光理论方法与技术

4.3 强激光应用的低吸收控性抛光理论方法与技术

4.4 典型高端抛光装备与性能指标

2024光学薄膜技术短课程培训

在光学薄膜技术的迅速发展和应用需求的推动下,对高性能光学产品的需求与日俱增。本短期课程将着重介绍光学薄膜技术的理论基础、制备工艺、应用场景以及未来发展趋势。通过结合理论研究与实践应用,探索光学薄膜技术在提高光学元件性能、实现光学器件功能多样化方面的关键作用。课程将从光学薄膜的设计原理、材料选择、薄膜沉积工艺以及表征检测等方面展开,结合实际案例深入探讨薄膜技术在光学器件中的应用与挑战。旨在培养具备光学薄膜技术应用能力的专业人才,为我国光学产业发展注入新的活力,推动我国光学制造业向着更高水平迈进。

一、培训时间:

2024年7月5日13:30-17:00(12:30-13:30签到)

二、培训地点:

西安建国饭店

三、主办单位:

中国光学工程学会

四、承办单位:

中国光学工程学会先进光学制造青年专家委员会

五、课程形式:

授课式,实例解析

六、课程说明:

学员自带电脑,自带TFC等类似软件,完成培训发放培训证书

七、讲师介绍:

张锦龙,同济大学物理科学与工程学院教授、博士生导师。主要从事光学薄膜、微结构器件方面的研究工作。承担中德合作重点项目等国家自然科学基金项目5项、863项目1项,基金委创新群体“强激光器件基础技术研究”的核心成员之一。在强薄膜相关技术领域开展了深入的研究工作,研制出一系列超强超短激光用高损伤阈值薄膜,达到国际先进水平,为我国超高功率激光装置的发展做出了贡献。以第一或通讯作者发表Photonics Research、Optics Letters等SCI论文30余篇;2019年获教育部科技进步奖二等奖(排名第1),入选2021年国家高层次青年人才;担任美国光学学会光学薄膜技术小组“Optical Thin Film technical Group”委员,光学学报(网络版)编委,中国宇航学会空间激光与太赫兹专业委员会委员。

刘华松,天津津航技术物理研究所研究员、博士生导师,兼任中国光学工程学会理事、中国光学工程学会青年专家委员会副主任委员、中国光学学会光学材料委员会委员、《Surface Science and Technology》编委,国家光学与光子学标准专家委员会光学材料与元件标准分委会委员,中国材料与试验团队标准委员会光学元件标准委员会/光电检测标准委员会委员。长期从事光学窗口与薄膜技术研究,主要研究方向为超低损耗光学薄膜技术、电磁屏蔽光学薄膜技术和光学窗口薄膜技术研究。先后主持国家自然科学重点基金、面向基金和青年基金、天津市自然科学重点基金、某重点基础项目等项目,发表学术论文80余篇,撰写专著2部、译著2部,授权国家发明专利60余项,获省部级奖励等9项。

梁海锋,西安工业大学教授,工学博士,博士生导师,专注光电功能薄膜器件研发和芯片集成研究,获陕西省“中青年科技创新领军人才”、“青年科技新星”等称号,获批多项军委科技委、装发等科研项目,授权发明专利20余项。在JMCC, ACSANN,OE等期刊发表论文60余篇,获陕西省技术发明奖二等奖1项(排名1),技术进步奖二等奖1项(排名3)。多项科研成果在西安市“秦创原”落地,相关技术在激光雷达、光谱制导和光谱成像等领域应用。

八、光学薄膜技术培训提纲

第一部分 高性能激光薄膜介绍

1.1 强激光薄膜研究背景和进展

1.2 面向强激光应用的薄膜设计

1.3 强激光薄膜材料及制备技术

1.4 强激光薄膜的性能测试方法

第二部分 红外光学薄膜的设计与制造

2.1 红外光学薄膜器件的需求

2.2 光学多层膜结构的设计方法

2.3 红外光学薄膜制造的工艺要点

2.4 红外光学薄膜器件的环境适应性

第三部分 光学薄膜滤光片设计

3.1 光学薄膜滤光片技术和产业概况

3.2 光学薄膜滤光片传统设计方法

3.3 超表面光学滤光片的设计方法

3.4 深度学习驱动的薄膜滤光片逆向设计

第四部分 光学薄膜滤光片制备及工艺装备

4.1 传统光学滤光片的制备方法及工艺

4.2 超表面光学滤光片的制备方法及工艺

第五部分 光学薄膜滤光片在光谱成像中的应用

5.1 渐变滤光片扫描光谱成像

5.2 阵列滤光片快照光谱成像

5.3 阵列滤光片压缩感知超光谱成像

九、报名人员要求:

基础知识要求:参与培训人员需要经过基本的物理学和光学基础知识训练。名额有限,报名从速。

1000元/人

同时报名两门课程或者同一单位2人以上报名,可以享受9折优惠

1.在线支付:线上报名完成后,可跳转到在线支付页面,选择“支付宝”在线完成支付。

2.汇款转账:

开户银行:工行北京科技园支行

户名:中国光学工程学会

账号:0200296409200177730

费用包含培训、教材、发票、证书和餐费,其他费用自理,开具“培训费”发票

十、同期活动:

十一、协议酒店:

会议酒店:西安建国饭店(陕西省西安市新城区互助路2号)

十二、联系人:

曹也(中国光学工程学会)

※Precision optical manufacturing

△Optical materials (glass, optical fiber, ceramic, crystal, etc.)

△Optical accessories (polishing fluid, polishing glue, polishing leather, grinding head, grinding wheel, etc.)

△Optical components (planar, spherical-aspherical, free-form surfaces, prisms, cylindrical mirrors, micro lenses, injection and molded components, etc.)

△Optical precision processing and testing equipment (fast polishing machine, milling machine, classical polishing machine, CNC polishing machine, robotic polishing, precision lathe, semiconductor wafer processing equipment; three coordinates, profiler, interference detector, sphere diameter meter, defect Disease instrument, stress instrument, etc.))

△Extreme manufacturing technology (micro-nano processing, super surface-super structure, special processing, etc.)

△Other

※Optical thin film technology and equipment

△Coating materials (film materials, coating accessories, etc.)

△Optical coating elements (reflective elements, windows, polarizers, filters, attenuators, etc.)

△Grating (coating, exposure, etching, etc.)

△Coating machine (electron beam, ion beam, sputtering, etc.);

△Related testing equipment (spectrophotometer, spectrometer, step meter, thickness gauge)

△Other

※Optical machine, lens and optical module

△Precision lens (mobile phone, car, infrared night vision, etc.)

△Telescopes, microscopes, optical analysis instruments, etc.

△CCD, CMOS, optical chip, etc.

△Optical platform, adjustment frame, electric stage, etc.

△Precision assembly technology

△Optical design, optomechanical integration

△Other

※Laboratory equipment

△Material mechanical properties test equipment

△Non-destructive testing instruments, analytical testing instruments, measuring instruments and equipment

△Software, laboratory information management system, etc.

△Environmental monitoring equipment

△Instrument accessories and parts

△Technology and products of supporting enterprises

Abstract Submission: https://b2b.csoe.org.cn/submission/YSAOM2024.html

Please submit a 500-800 words abstract in English for technical review purposes that is suitable for publication. If accepted, the contact author will receive notification of acceptance by email. Before you submit the abstract and the manuscript, Please refer to the following examples.

Abstract Submission Deadline: 15 June, 2024(Final Round)

Supported Journals:

PhotoniX(SCI)、

Light:Science & Applications(SCI)、

Optical Engineering(SCI)、

Journal of Micro/Nanolithography、MEMS、and MOEMS(SCI)、

Photonic Sensors (SCI)、

Opto-Electronic Advances(OEA)(SCI)、《信息与电子工程前沿(英文)》(FITEE)(SCI)、

International Journal of Extreme Manufacturing(SCI)、

Micromachines(SCIE)、《红外与激光工程》(Ei)、《液晶与显示》(ESCI)、《中国光学》(ESCI、Ei)、《光子学报》(ESCI、Ei)、《发光学报》(Ei)、《光学精密工程》(Ei)、SPIE Proceedings(Ei)、

Nanomanufacturing and Metrology (Ei)、

Light: Advanced Manufacturing(DOAJ)、

eLight、《光电工程》、《航天返回与遥感》、《飞控与探测》etc

Abstract template:  Author_abstract template YSAOM2024.doc

Poster template(80cm*90CM):

Author_abstract template YSAOM2024.doc

Poster template(80cm*90CM):  Poster Template.pptx

Poster Template.pptx

(1)报名方式

无论有无投稿,均欢迎注册参会!

参会者请务必到以下网址进行会议注册:

会议费:3250元/人,2024年6月14日前缴费优惠为3050元/人。

学生优惠为2250元/人(不含在职学生),2024年6月14日前缴费优惠为2050元/人。。

会议费包括资料袋、报告文集、会议指南文件、会议杂支、税等,不含论文版面费和住宿费。论文版面费2500元,相同第一作者不超过两篇。

(2)付款方式:

1.在线支付:注册完成后,可跳转到在线支付页面,选择“支付宝”在线完成支付。

2.汇款转账:

开户银行:工行北京科技园支行

户名:中国光学工程学会

账号:0200296409200177730

汇款时作者请务必注明“姓名+稿件编号”,非作者请注明“YS+姓名”,以便核对。

会议将提供正规会议费发票。

(3)会议注册费退款

注册费会前2周(14天)可退全款,超过2周时间因产生会议成本将不再支持退款。

(4)会议注册费发票

会议注册费发票将在会前两周和会后两周集中处理。

1.Participants must register for the conference at the following website:

Website:

For Chinese Attendee:

For Foreign Attendee:

Conference fee: RMB 3,250/pp, and the discount for payment before 14th June, 2024 is RMB 3,050/pp.

The student discount is RMB 2,250/pp (not including on-job students), and the discount for payment before 14th June, 2024 is RMB 2,050/pp.

Conference fees include information kits, report essays, conference guide documents, conference miscellaneous expenses, taxes, etc., excluding paper layout fees and accommodation fees.

2. online payment: After registration, you can jump to the online payment page and select "Alipay" to complete the payment online.

3. Remittance transfer:

Beneficiary,s Name&Address:CHINESE SOCIETY FOR OPTICAL ENGINEERING/NO.1 BLDG HAIYING ROAD FENGTAI DISTRICT BEIJING CHINA

Bene,s A/C No:0200296409200177730

SWIFT CODE:ICBKCNBJBJM

BENEFICIARY BANKER,S NAME:Industrial and Commercial Bank of China Beijing Municipal Branch,Beijing,PRC

When remittance, the author must indicate "name + manuscript number", non-authors please indicate "YS + name" for verification.

The meeting will provide a formal meeting fee invoice.

Topics:

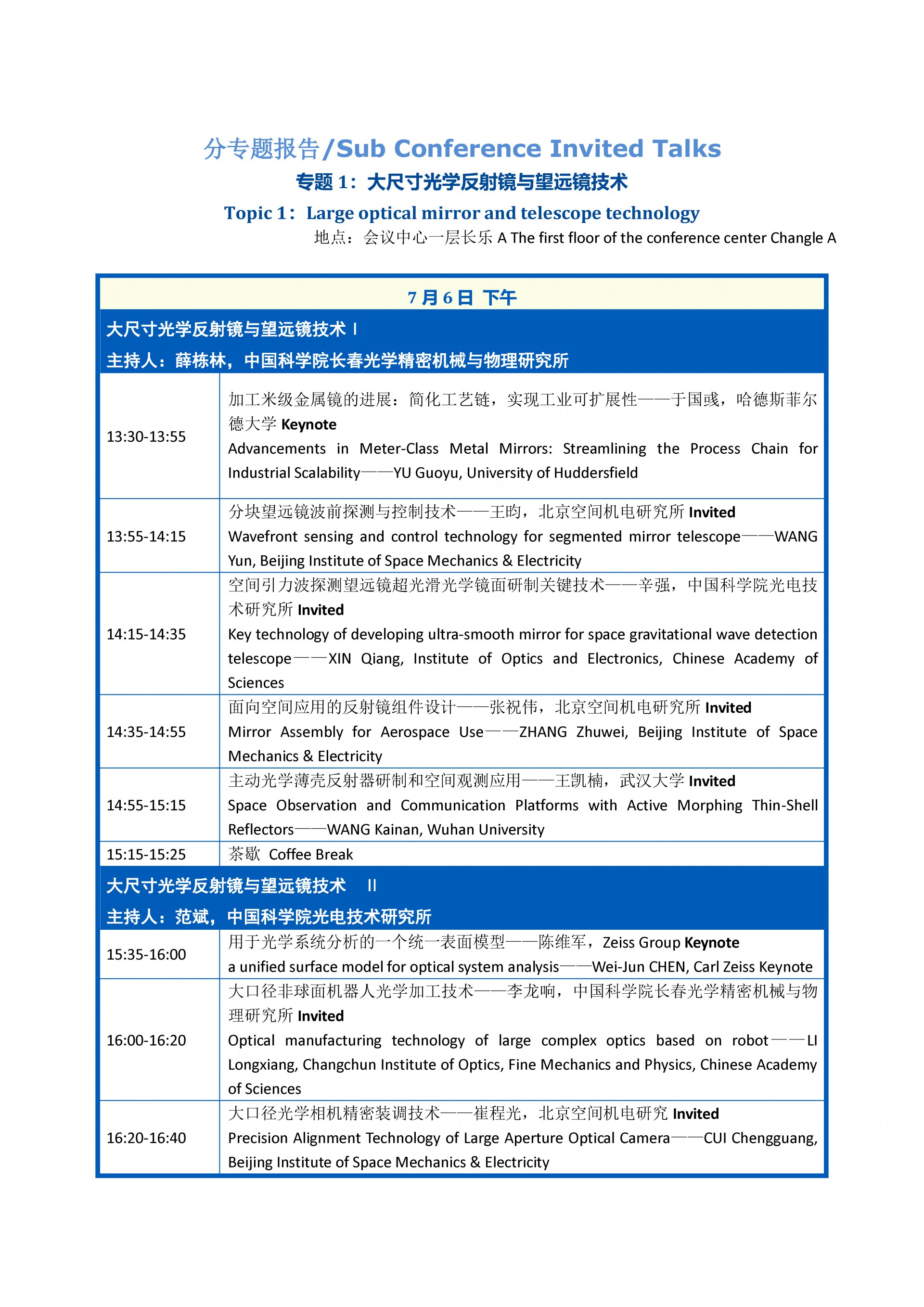

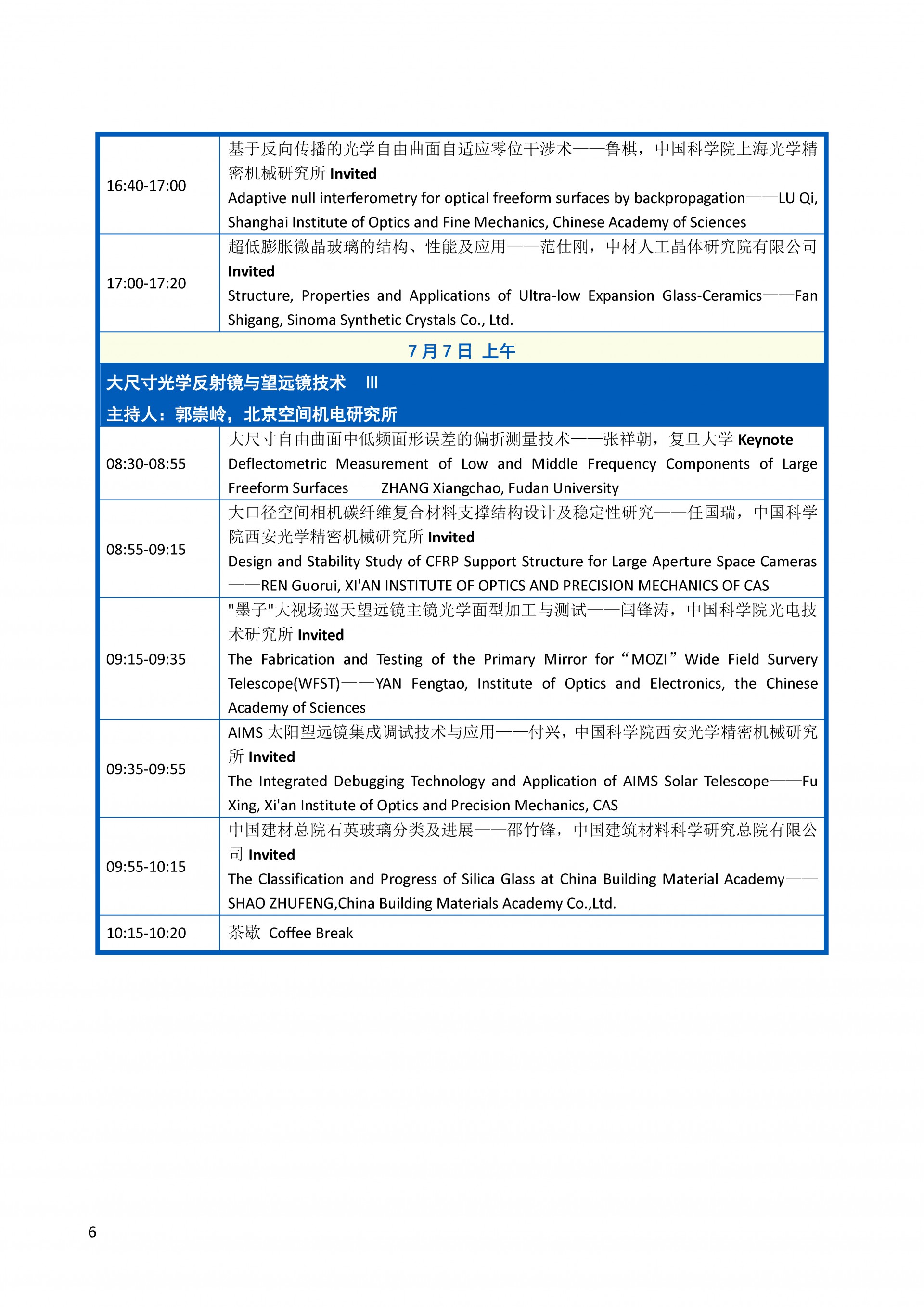

Topic 1:Large optical mirror and telescope technology

The topic is intended to reflect the latest progress in the technology and equipment of large optical mirrors and telescopes, including but not be limited to: scientific objective observation and optical engineering technology, optical optimization design of large lightweight mirrors, advanced optics and structural materials, high-precision and high-stability mirrors and structural support technology, measurement and control technology of segmented synthetic aperture optical system, integrated design of large photoelectric instruments, active optics and adaptive optics technology, giant tracking structure and its high-precision stability control technology, space and earth consistency technology of telescope, precision assembly technology of large photoelectric instruments, complex optical mirrors and systems test and measurement technology, high performance and intelligent manufacturing technology of large optical mirrors.

Chair:

XUE Donglin, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

Co-Chairs:

Chen,Wei-Jun,Zeiss Group

FAN Bin, Institute of Optics and Electronics, CAS

GUO Chongling, Beijing Space electromechanical Research Institute

Topic 2:Micro-nanostructure optics and manufacturing technologies

This topic intends to reflect the latest progress in micro-nanostructure optics and manufacturing technologies, which will focus on (not limited to): new manufacturing technologies of micro-nanostructure optics and microelectronic integrated devices,high-efficiency sub-wavelength structural manufacturing methods, new mechanisms and methods of super-resolution/super-diffraction manufacturing, new manufacturing technologies of short/ultra-short laser pulses, optical super-resolution additive/subtractive manufacturing technologies and applications, optical performance evaluation methods of micro-nano manufacturing and their matched optical high-precision detection technologies and etc..

Chair:

ZHOU Tianfeng, Beijing Institute of Technology

Co-Chair:

GAO Ping, Institute of Optoelectronic Technology, CAS

CHEN Qidai, Jilin University

LI Ming, Xi'an Institute of Optics and Precision Mechanics of CAS

XU Ting, Nanjing University

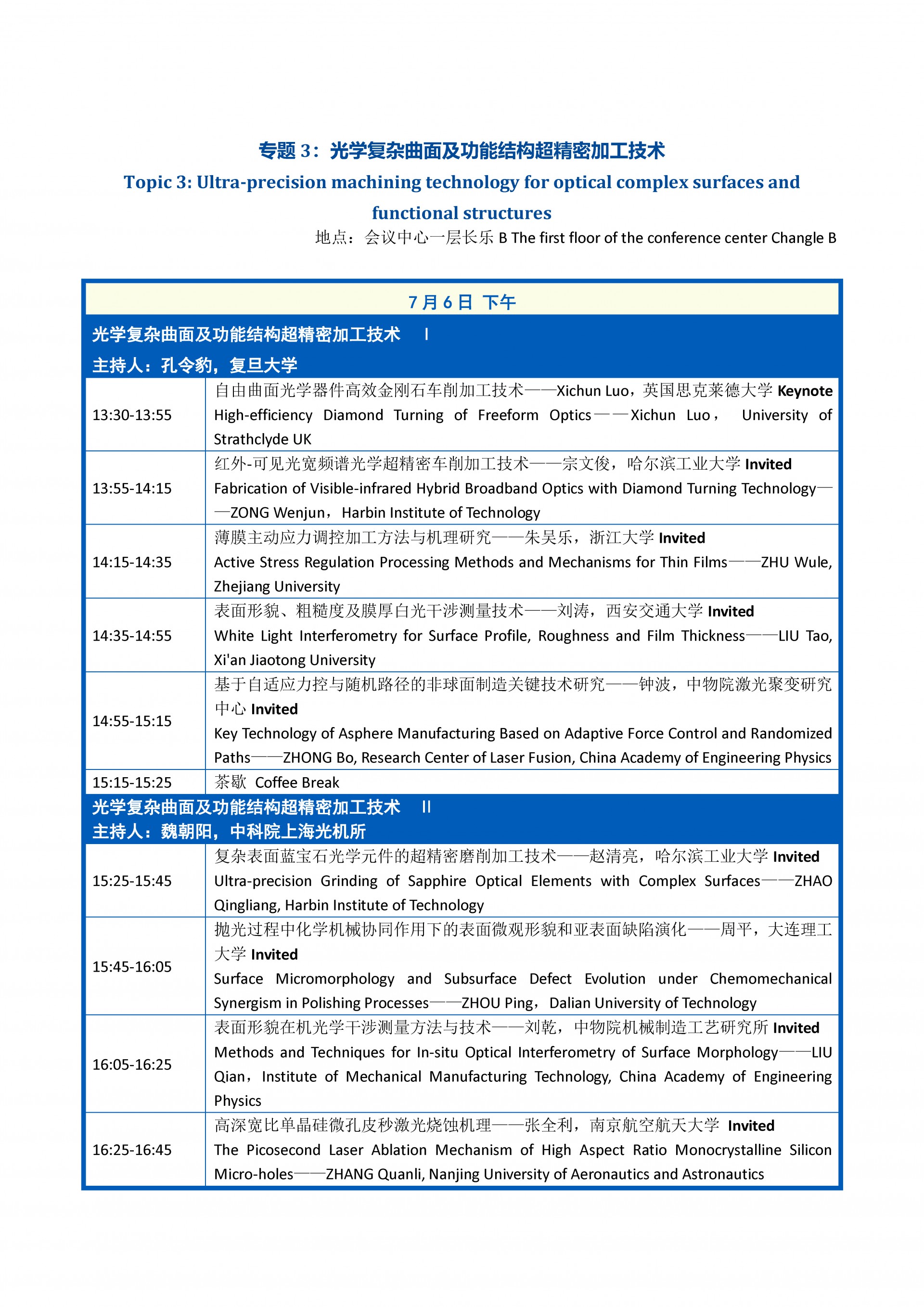

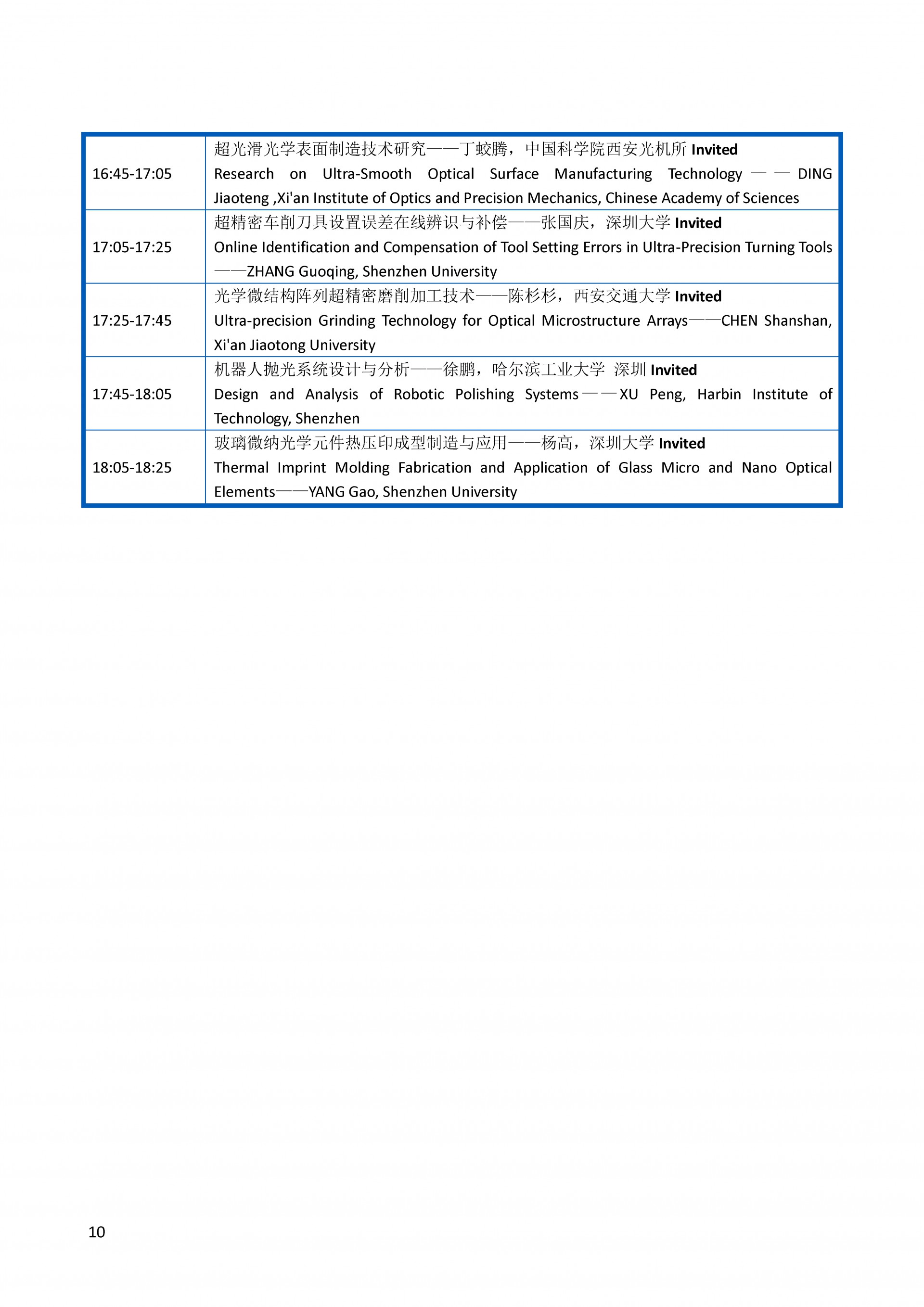

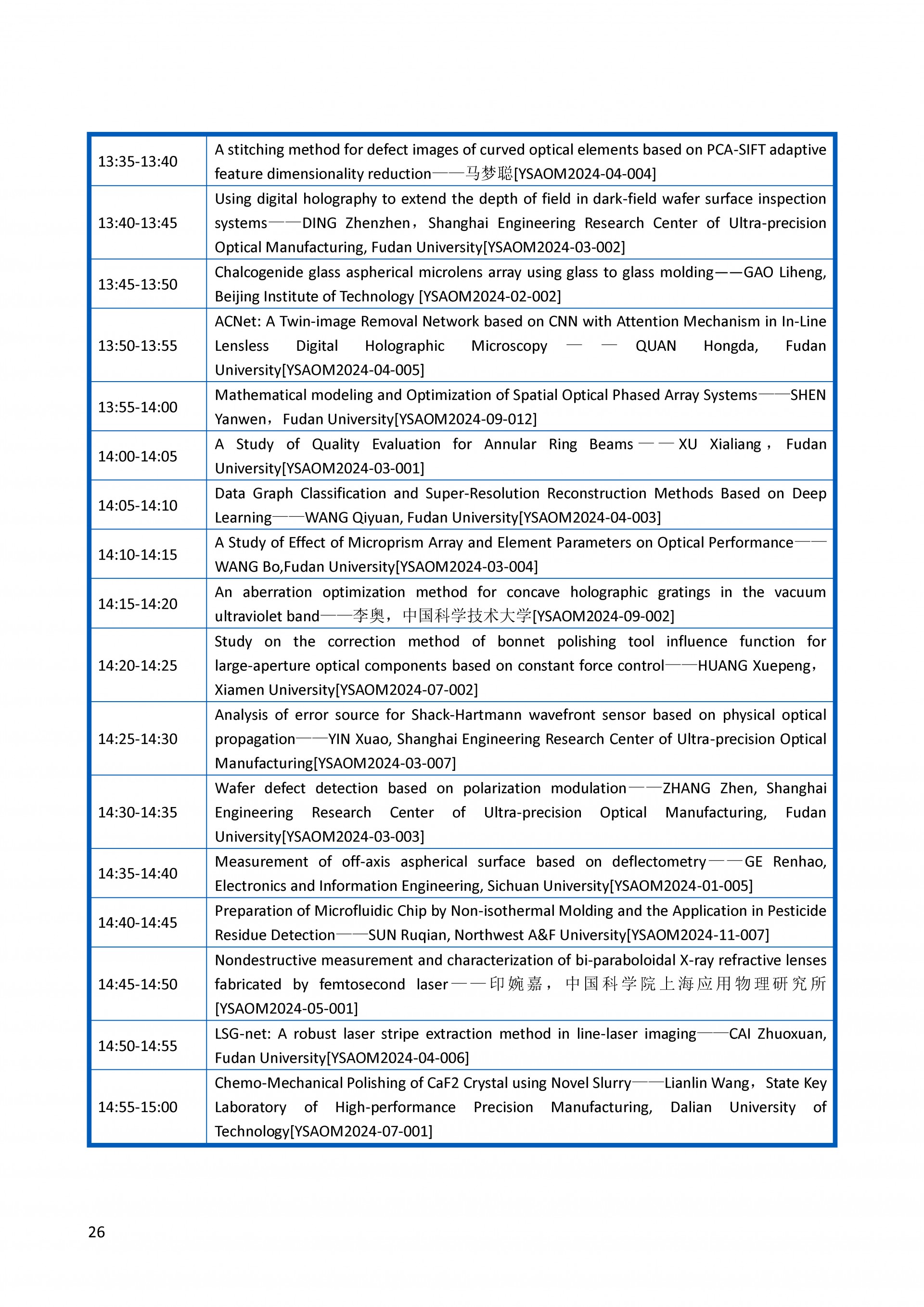

Topic 3: Ultra-precision machining technology for optical complex surfaces and functional structures

This topic intends to reflect the latest developments in ultra-precision machining technology for optical complex surfaces and functional structures, including but not limited to: ultra-precision turning, milling, grinding, polishing and other processes, laser processing, new micro-nano processing, molding and injection molding, micro-nano imprinting, adding and subtracting material composite technology, multi-energy field auxiliary processing, tool design and manufacturing, machining path planning and optimization, process chain process modeling and simulation, materials removal mechanism, surface full-frequency error analysis and control, machining and testing integration, etc.

Chair:

KONG Lingbao, Fudan University

Co-Chairs:

Xichun Luo, University of Strathclyde, UK

WEI Chaoyang, Shanghai Institute of Optics and Fine Mechanics, CAS

CAO Zhongchen, Tianjin University

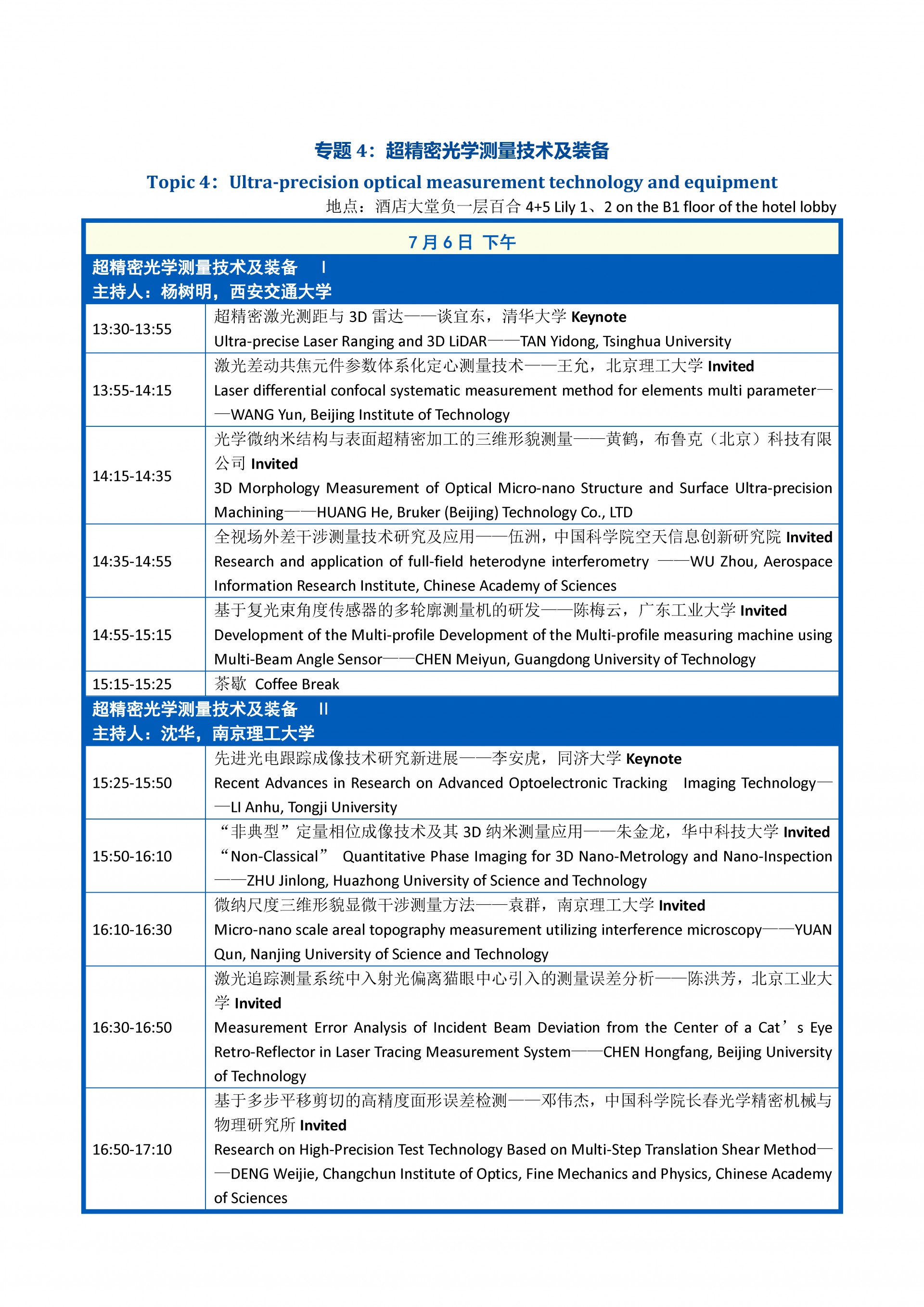

Topic 4:Ultra-precision optical measurement technology and equipment

This topic intends to reflect the latest developments in optical measurement technology and equipment. The focus includes but is not limited to: optical testing and measurement based standards, metrology and online digital calibration, measurement issues in the advanced optical manufacturing process, measurement methods of optical components geometric parameters and physics characteristic, development of key optical devices in optical measurement systems, test and measurement technologies based on optical devices (gratings, optical fibers, etc.), advanced measurement methods in micro-nano manufacturing, macro and micro measurement techniques, precision and ultra-precision machining measurement, precision and modern optical technology and instruments for ultra-precision measurement, data processing methods in optical measurement, new optical testing and measuring principles, new optical measurement instruments and equipment, new instrument theory and design methods, micro-nano testing and measuring methods, extremely small sizes Optical measurement methods, vision measurement technology, etc.

Chair:

YANG Shuming, Xi’an Jiaotong University

Co-Chairs:

LI Wenhao, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

LU Zhengang, Harbin Institute of Technology

SHEN Hua, Nanjing University of Science and Technology

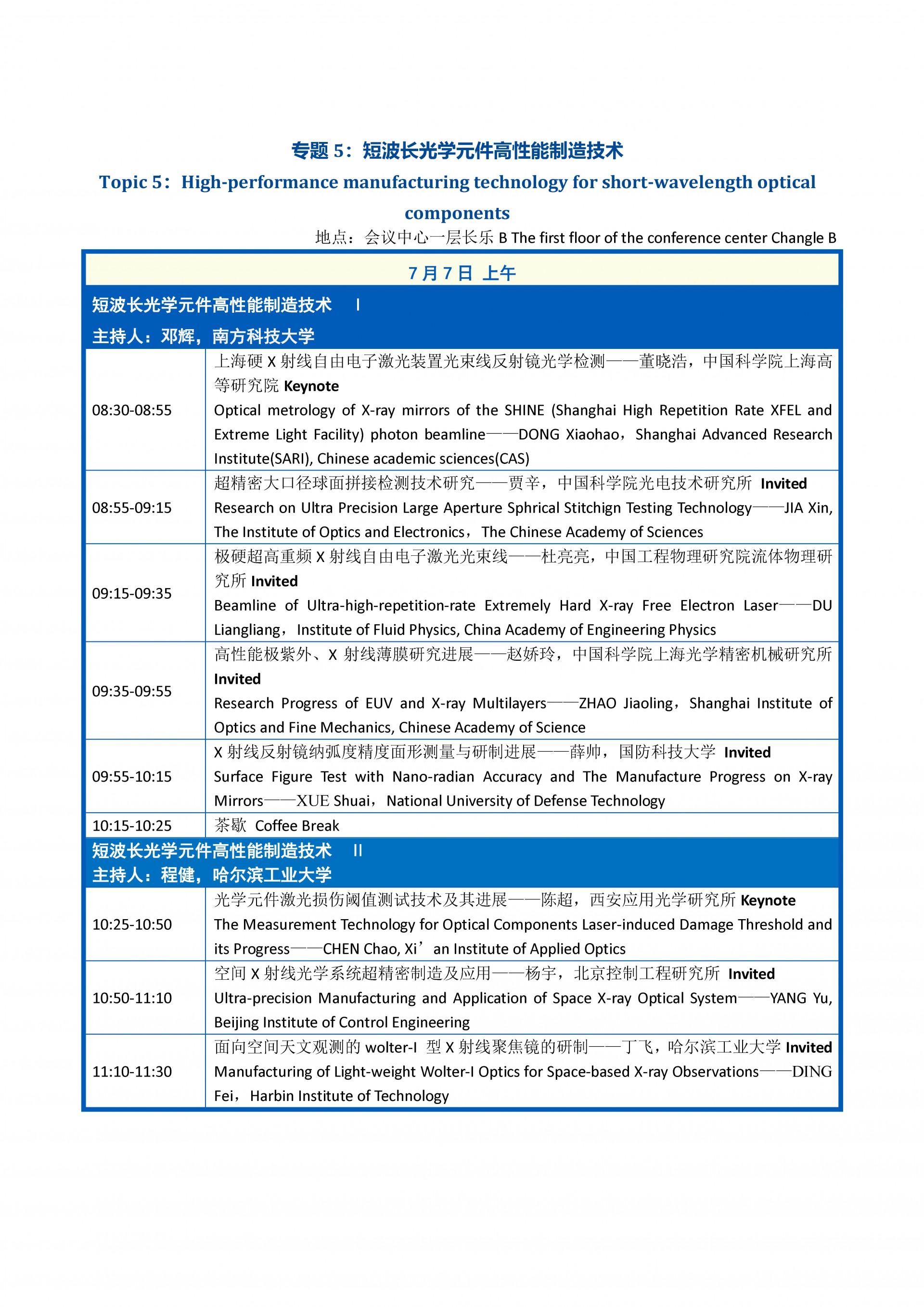

Topic 5:High-performance manufacturing technology for short-wavelength optical components

This topic intends to reflect the latest developments high-performance optical system manufacturing technology, including but not limited to: manufacture of ultraviolet, X-ray and other short-wavelength optical components, manufacture of lightweight optical systems, anti-damage manufacturing of high-energy laser components, processing and testing technology of glancing incidence optical components, detection and evaluation technology for ultra - precision optical components, etc.

Chair:

PENG Xiaoqiang, National University of Defense Technology

Co-Chairs:

LI Ming, Institute of High Energy Physics, CAS

KANG Chengwei, Xi’an Jiaotong University

DONG Xiaojie, Shanghai Institute for Advanced Study, Chinese Academy of Sciences

DEND Hui, Southern University of Science and Technology

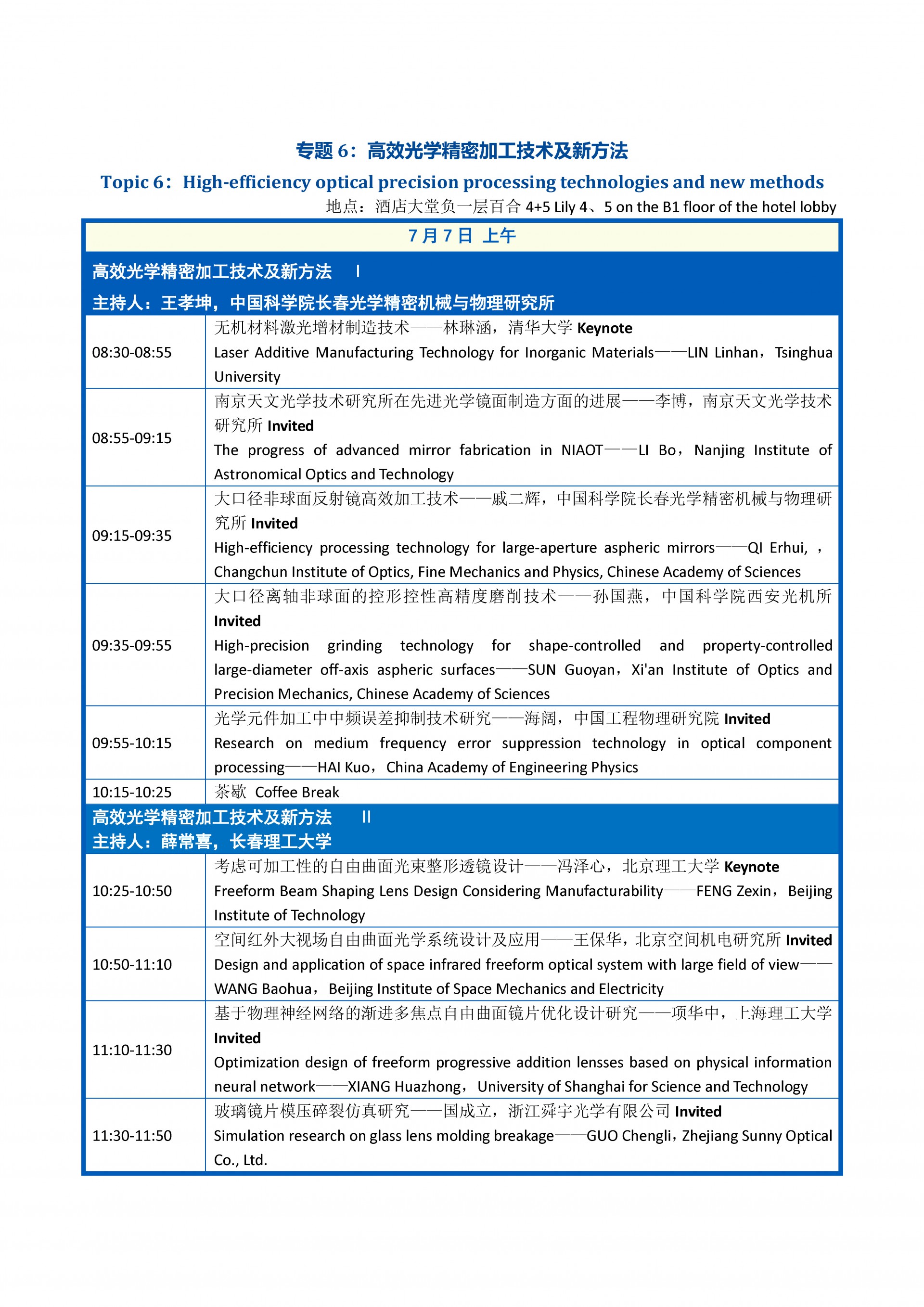

Topic 6:High-efficiency optical precision processing technologies and new methods

This topic intends to reflect the latest developments in ultra-precision optical precision processing of new processes, new technologies and new methods, including but not limited to: ultra-precision machining technology of single point diamond in optical ultra-precision machining technology, magneto-rhelogical finishing technology, ion beam machining technology, numerical control grinding and polishing technology, glass molding technology, the efficient implementation approach, method and process optimization of injection molding technology, and the feasibility of optical manufacturing technology in the optical design process, put forward new processes, new materials, new methods, new ideas and new concepts, realize innovative and efficient advanced manufacturing technology of precision optics, such as complex surfaces, metal optics, hard-machined material optics, and realize the optimization of new processes, new technologies, new methods and technological approaches for efficient precision manufacturing technology, and promote the efficiency and process optimization of optical precision processing technology.

Chair:

WU Rengmao, Zhejiang University

Co-Chairs:

WANG Xiaokun, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

Daewook Kim, University of Arizona

XUE Changxi, Changchun University of Science and Technology

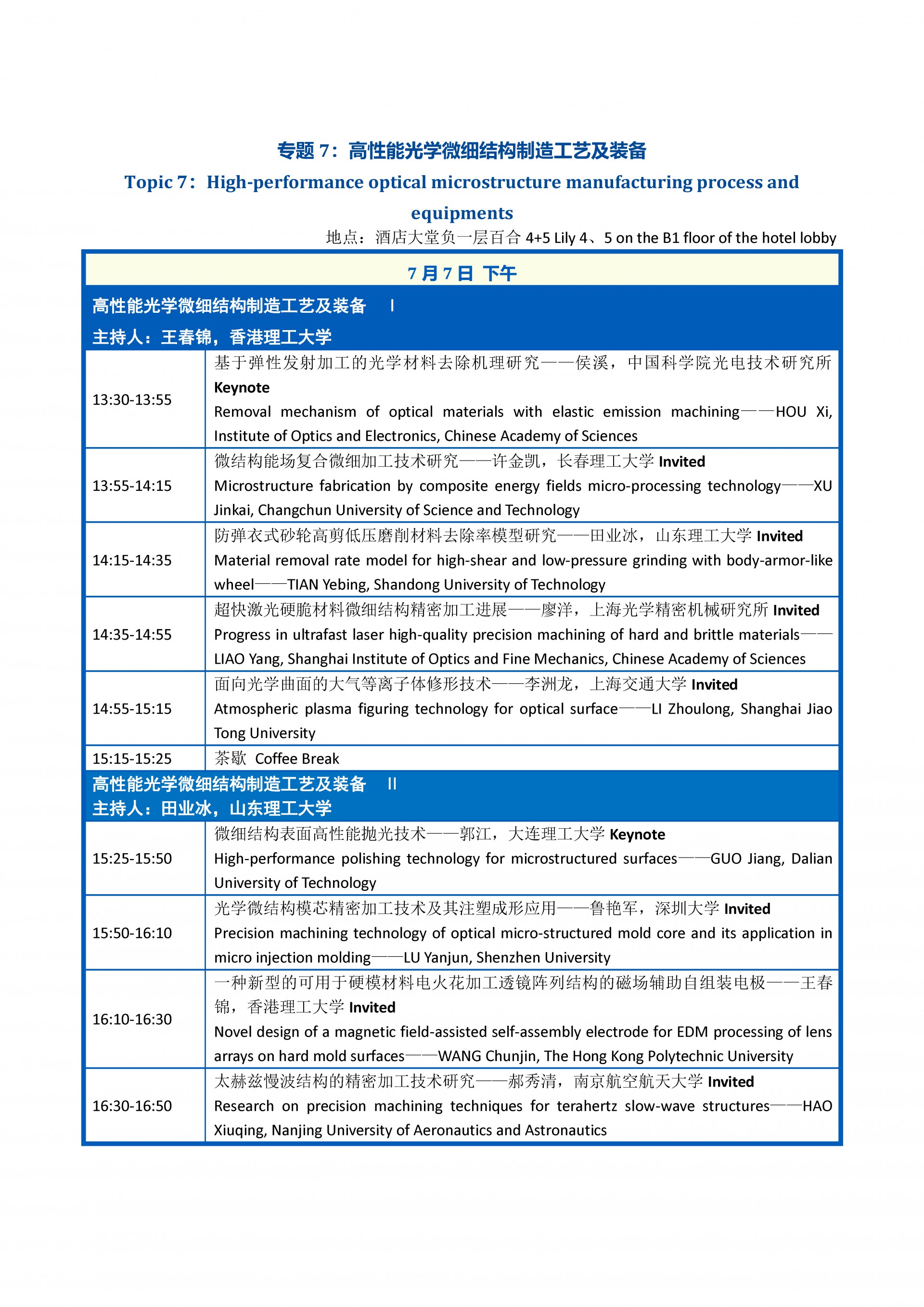

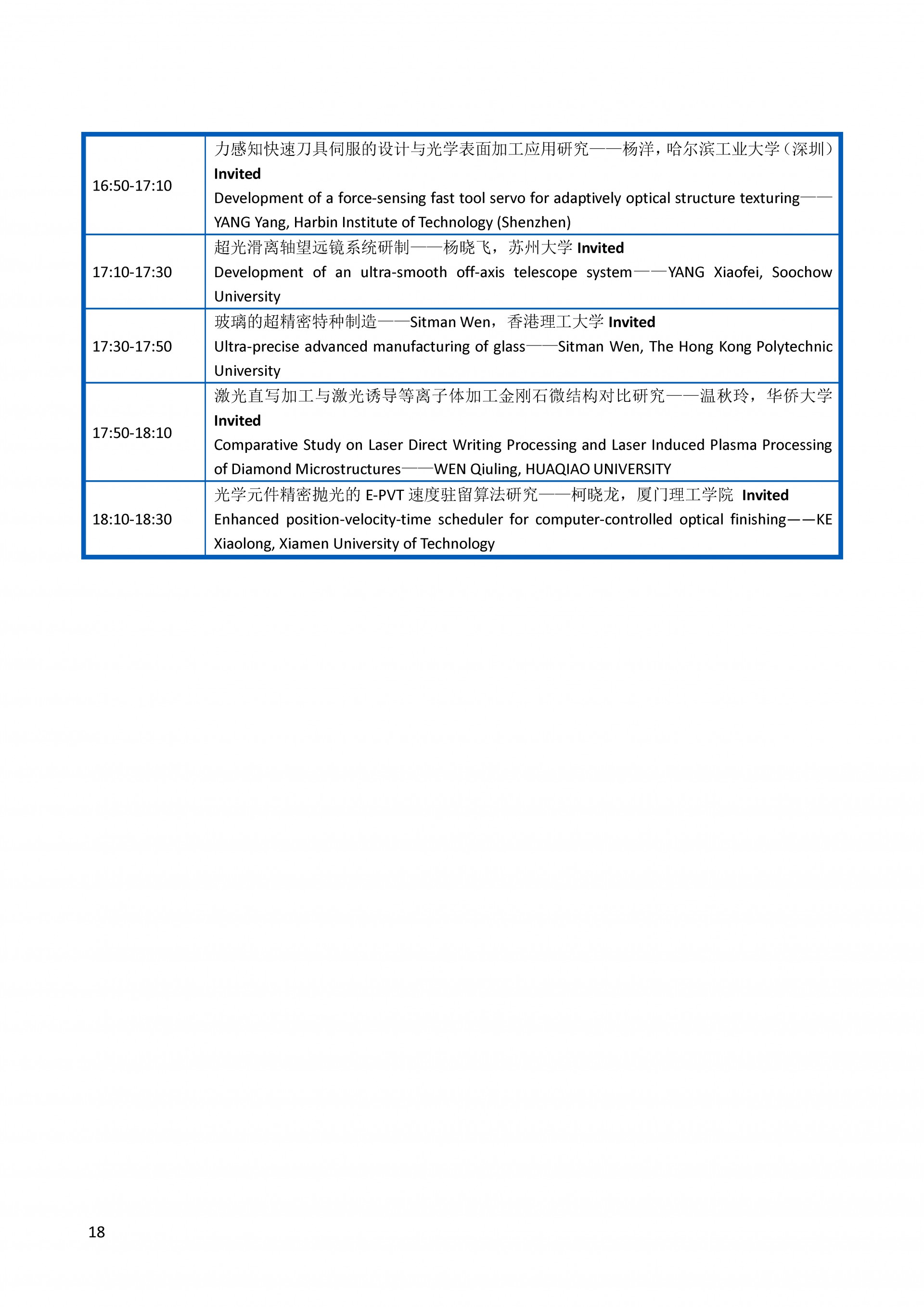

Topic 7:High-performance optical microstructure manufacturing process and equipments

This topic intends to reflect the latest progress in High-performance optical microstructure manufacturing process and equipments, including but not limited to: high-performance optical microstructure ultra-precision processing technology for optical microarray structures with size characteristics of tens to hundreds of microns, high-performance optical microstructure conformal polishing technology, optical microstructure efficient and ultra-low damage processing technology, optical microstructure rapid and high-precision integrated in-situ detection technology, microstructure optical component performance evaluation technology, Large-scale microstructure, high-precision rapid manufacturing technology, etc.

Chair:

GUO Jiang, Dalian University of Technology

Co-Chairs:

TIAN Yebing, Shandong University of Technology

WANG Chunjin, The Hong Kong Polytechnic University

DAI Bo, University of Shanghai for Science and Technology

LU Yanjun, Shenzhen University

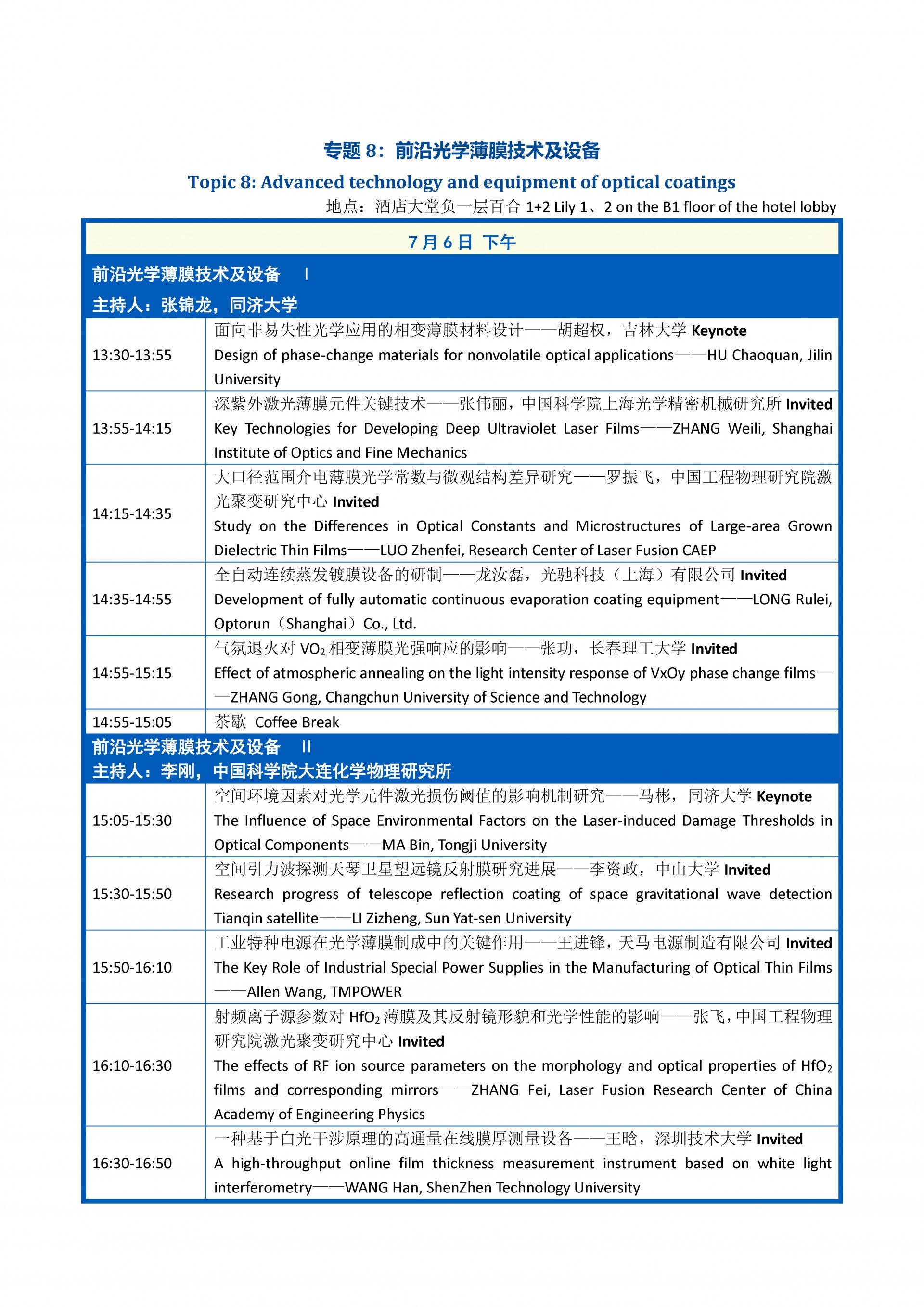

Topic 8: Advanced technology and equipment of optical coatings

This topic intends to reflect the latest developments in optical coating materials, design, preparation and characterization technologies and the applications results of major projects. The focus includes but not limited to: new optical coating materials covering the optical spectrum from X-ray to far-infrared, and nanostructure coating materials; high-performance optical coating design and manufacturing technology represented by X-ray, laser and infrared typical optical spectrum, multi-functional surface film design and manufacturing technology, multifunctional optical coating design and manufacturing technology (light, heat, force, Electricity); Characterization technology of optical coatings for application requirements, such as ultra-wide spectrum optical constant characterization technology, low loss optical coating performance testing technology, special environmental optical coating performance evaluation and testing methods, etc.; Latest progress of optical coating manufacturing equipment and testing instruments, etc.

Chair:

ZHANG Jinlong, TongJi University

Co-Chair:

LIU Huasong, Tianjin Jinhang Institute of Technical Physics

CHENG Xinbin, Tongji University

Sven Schroder, IOF Franhofer, Germany

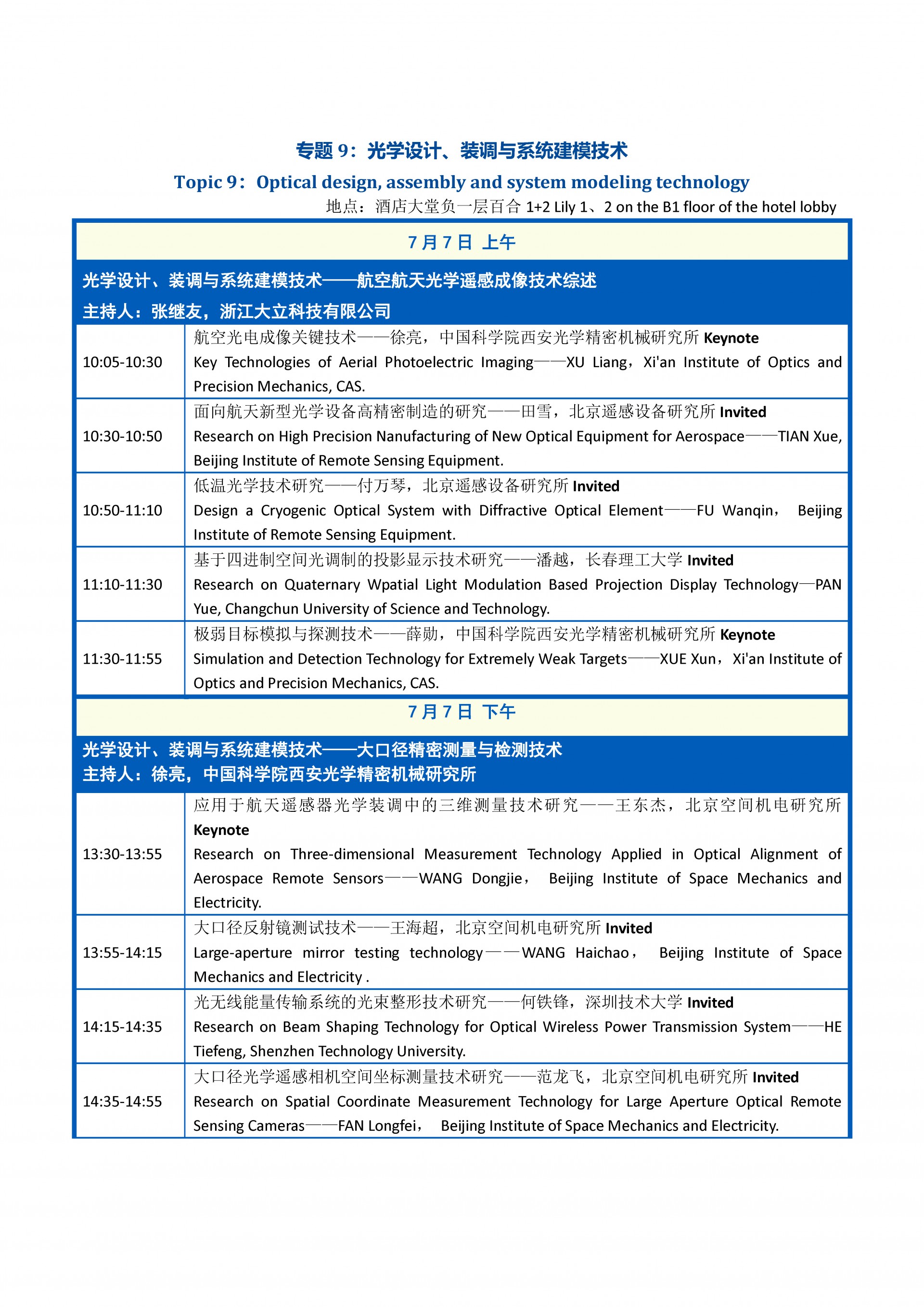

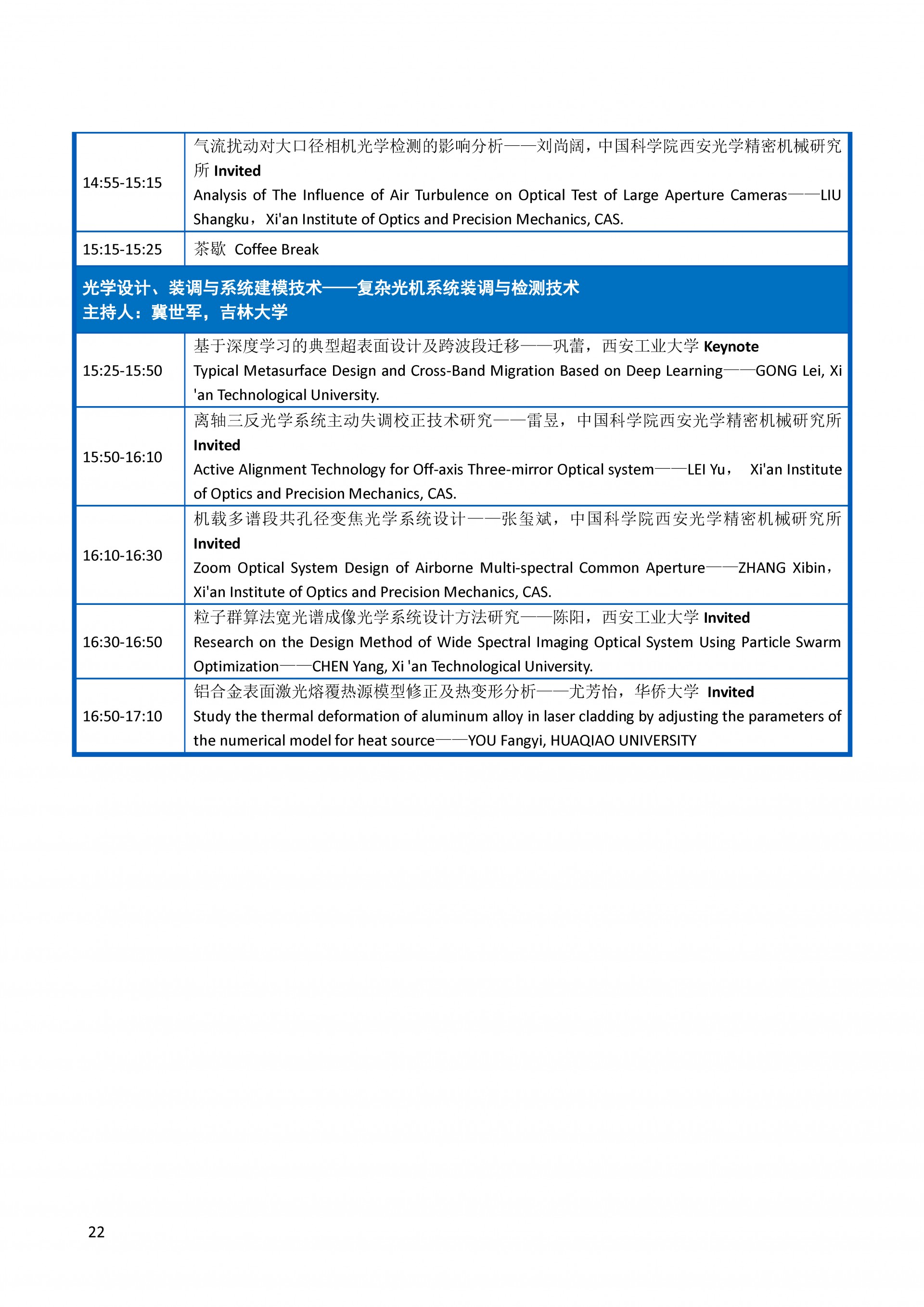

Topic 9:Optical design, assembly and system modeling technology

This topic intends to reflect the latest research development of optical design, assembly and system integration test, digitization and systematic engineering simulation in optical field, the focus includes but not limited to: new optical systems, new spectral imagers, new precision metrology and laser measurement instruments, aerospace optical remote sensing systems, laser detection and lidar products and other optical design and simulation, optical stray light simulation and suppression design, optical system installation and performance evaluation technology, complex optical system installation and testing technology, spatial complex focal plane splicing and registration testing technology Internal orientation element and distortion testing technology, stress-free gluing and stress-free assembly technology; Model-driven optical system engineering, engineering basic database, core theory and algorithm model, virtual manufacturing system, digital twinning technology, optical modeling and accuracy analysis, optical software system engineering, complex optical system algorithm optimization scheme, optical manufacturing equipment test and control system, optical system performance analysis and application evaluation, etc.

Chair:

XU Liang, Xi'an Institute of Optics and Precision Mechanics of CAS

Co-Chairs:

ZHANG Jiyou, Zhejiang Dali Technology Co., Ltd

JI Shijun, Jilin University

Topic 10: Manufacturing and applications of optofluidic chip and liquid crystal optics

This topic intends to reflect the latest developments in manufacturing and applications of optofluidic chip and liquid crystal optics, the focus includes but not limited to: discussing the research progress of using microfluidic technology and liquid crystal technology to manufacture various optical components, and using research progress on the preparation of microfluidic chips with different optical manufacturing technologies. Analyze the characteristics and advantages of optical flow control components and liquid crystal Liquid crystal, and demonstrate the application of optical flow control technology in optical inspection, biomedicine, chemical analysis, and real-time inspection. It aims to use these new technologies to provide better solutions for the next generation of precision optical systems such as biochemical analysis, medical testing, and environmental monitoring.

Chair:

ZHANG Dawei, University of Shanghai for Science and Technology

Co-Chairs:

Francis Lin, University of Manitoba, Canada

YANG Yi, Wuhan University

ZHANG Xuming, The Hong Kong Polytechnic University

ZHENG Zhigang, East China University of Science and Technology

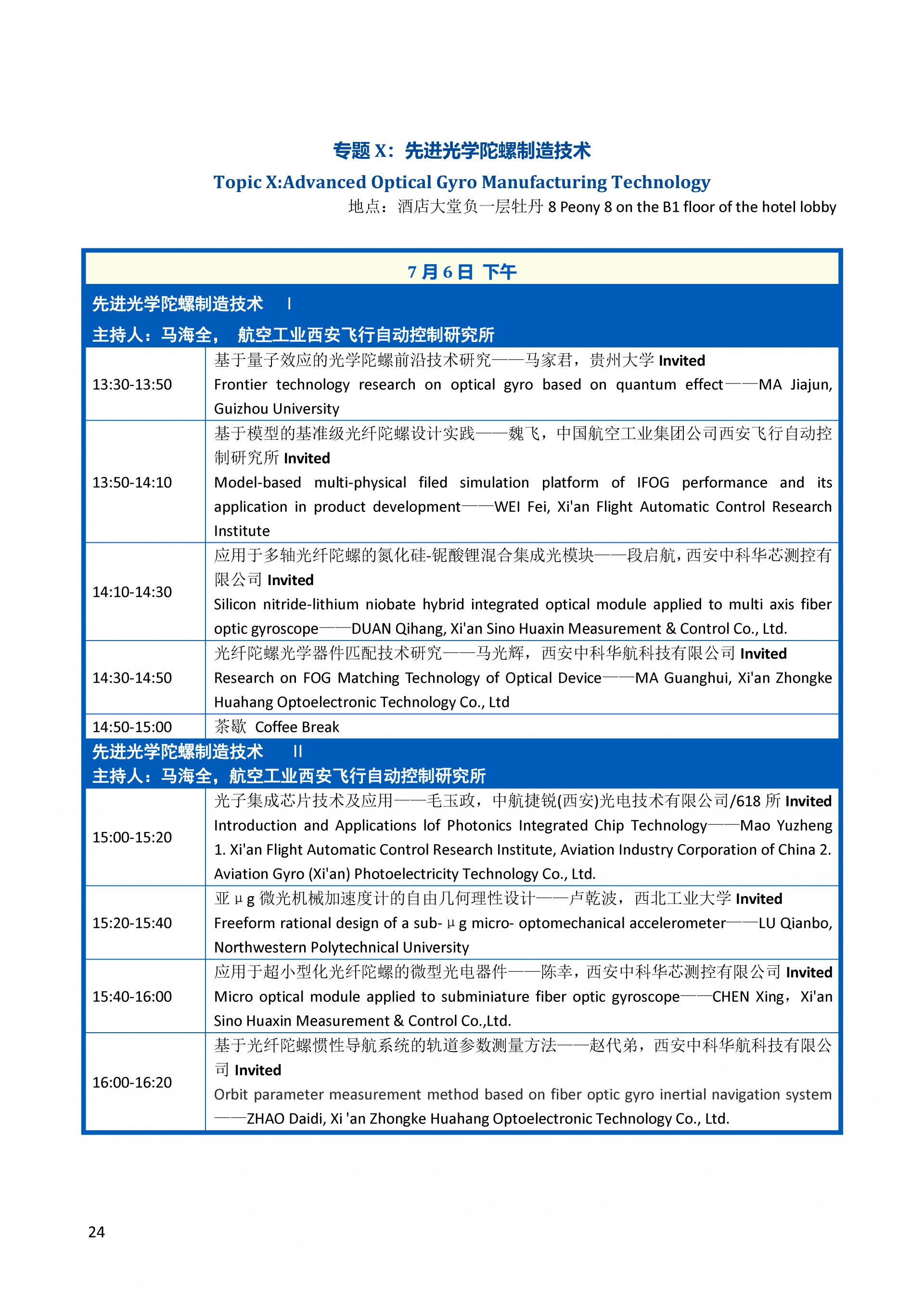

Topic X: Optical gyro manufacturing technology

This topic is intended to reflect the latest research progress of advanced optical gyroscopes, including but not limited to: photon integrated chip design, photon chip coupling seal testing technology, silicon -based optical waveguide research, optical path transmission model establishment, optical gyroscopy back radiation analysis, optical optics, optics Gyroscopy with testing technology, multi -axis gyroscopy fusion light road design and simulation, error calibration and initial standard technology, error compensation and inhibitory technology, high -precision multi -physical field model construction technology, output bias or atresia effect, etc.

Chair:

XU Jintao, Xi 'an Inertia and Sensing Engineering Research Center

Co-Chairs:

MA Jiajun, Guizhou University

LIU Ying, Xi’an University of Posts & Telecommunications

SPIE Proceedings:

通过百度网盘分享的文件:Vol. 13280 COM24 Master Digital Fil...链接:https://pan.baidu.com/s/1qkJvdVPykODG5YpWdeAWYg?pwd=kq3j

提取码:kq3j

In today's world, science and technology have made rapid progress. The rapid development of aerospace, energy, information, weapons and equipment, large scientific installations, and other technological fields, such as space observation, large light sources, EUV photocurrent machines, synchronous radiation, etc., have put forward urgent demand for advanced optical manufacturing technology. Advanced optical manufacturing technology is moving towards optical high-performance requirements and intelligent manufacturing, presenting the trend of multi-disciplinary development and integration development of nano-nano, and even atomic-level ultra-precision manufacturing, ultra-precision measurement, intelligent sensing and control, materials, mechanics and other disciplines.

The "2nd Conference on Advanced Optical Manufacturing Technologies & Applications & 4th Forum of Young Scientists on Advanced Optical Manufacturing " meeting hosted by the Chinese Society for Optical Engineering (CSOE) was held in Xi'an in July 5-7 2024, focusing on discussing the latest development developments of advanced optical manufacturing technology and equipment.

The accepted papers are published in the SPIE International Conference Proceedings Sequence and its digital library, indexed by EI core search. At the same time, many domestic high-quality optical journals participate in the full-text collection of this conference. Activities include conferences, exhibitions, training and other forms.

Highlights:

International Conference includes expert talks (invited or applied), oral speeches, posters, excellent student paper selection (certificate issuance), paper publication, etc.

Exhibition includes product exhibition, university-enterprise matchmaking meeting, institute-enterprise matchmaking meeting, investment and other activities.

Short courses and workshops provide relevant practitioners with technical and skill training such as case analysis, concept explanation and skill training.

Industrialization Forum focuses on significant applications and key technologies in the field of optics, and invites representative enterprises and universities to discuss hot topics such as product demands and technical breakthrough.

Visit: Local enterprises and universities welcome participants voluntarily sign up for visits.

●参观拜访(大会参会人员均可报名,由于场地限制,接待能力有限,参观人员需提前报名,具体名额采取先到先得方式)

LV Zichen(CSOE)

lvzichen@csoe.org.cn,13810226340

吕子辰(中国光学工程学会)

lvzichen@csoe.org.cn,13810226340

SPIE Proceeding (EI)

Presenting and publishing your research in Proceedings of SPIE has multiple professional and business benefits. Read The Value of Proceedings white paper for a comprehensive discussion.

Proceedings of SPIE are uniquely valuable as they are used by researchers worldwide, and lead in patent cites among optics and photonics collections. They frequently rank among the 50 most used serials, out of 50,000 analyzed by Ex Libris. If it is ready for journal publication, your proceedings paper can be submitted with minimal or no revision for consideration in the relevant SPIE journal.

Indexed and accessible

SPIE partners with relevant scientific databases to enable researchers to find Proceedings of SPIE. They are indexed in Web of Science, Scopus, Ei Compendex, Inspec, Google Scholar, Astrophysical Data System (ADS), CrossRef, and other scholarly indexes, and are widely accessible to leading research organizations, conference attendees, and individual researchers.

SPIE Journals

SPIE publishes ten significant journals in major areas of optics, photonics, and imaging.

These journals welcome submission of journal-ready manuscripts that are derived from conference papers, as appropriate for each journal.

See the SPIE policy on submission of manuscripts derived from conference papers.

Conference Proceedings Papers

Submissions to SPIE journals based on reports that have been submitted to or published in a conference proceedings should adhere to the following guidelines:

Distinction between proceedings and journal papers:

Conference proceedings provide a vehicle for rapid reporting of ideas, techniques, and results. It is not uncommon for these reports to be somewhat incomplete and inconclusive. The purposes of proceedings papers range from snapshots of recent or continuing work to the reporting of a completed work or project. Journal papers are expected to be original, complete, and polished; to contain comparisons of theoretical and experimental results; and to include substantial conclusions and comprehensive references to other work.

Revision of conference proceedings manuscripts for journal submission:

SPIE publication policy permits manuscripts based partly or entirely on scientific content previously reported in SPIE proceedings to be submitted to SPIE journals. Furthermore, SPIE permits manuscripts based partly or entirely on scientific content previously reported in a non-SPIE conference to be submitted to SPIE journals so long as the copyright policies of the non-SPIE conference are properly adhered to (see below). In most cases, it is anticipated that the journal submission will represent a substantively expanded, refined, or otherwise revised manuscript relative to the proceedings paper to fully satisfy the standards of significance, originality, and presentation quality expected in a journal submission that is being considered for acceptance through the journal peer-review process. A manuscript submitted to an SPIE journal that incorporates minimal or no revisions over a prior or concurrent SPIE proceedings paper may be considered for publication in an SPIE journal and admitted into the peer-review process provided the submission fulfills the requirements of significance, originality, and completeness expected in a journal submission. SPIE does not consider publication of an accepted journal article based on a prior proceedings paper to constitute double publication.

Disclosure:

If a manuscript (or portion of a manuscript) was previously published in a conference proceedings or is under consideration for publication in a conference proceedings, this information must be disclosed when the manuscript is initially submitted to an SPIE journal. Authors should also reference or acknowledge the prior proceedings paper within the submitted journal article.

Copyright:

SPIE copyright policy permits authors to submit derivations of their proceedings papers to their journal of choice. Submissions to SPIE journals are permissible provided the other expectations described herein are satisfied. Authors submitting to journals published by other publishers should verify that publisher's copyright and submission policies. Authors wishing to submit papers that were presented at or published in a conference proceedings sponsored by organizations other than SPIE are responsible for adhering to the copyright policies related to that presentation or publication and are expected to disclose the prior presentation or publication history of the submission.

Journal submission format:

All proceedings manuscripts submitted to an SPIE journal must be prepared according to the guidelines provided here.

See more information at:

https://spie.org/publications/spie-journals

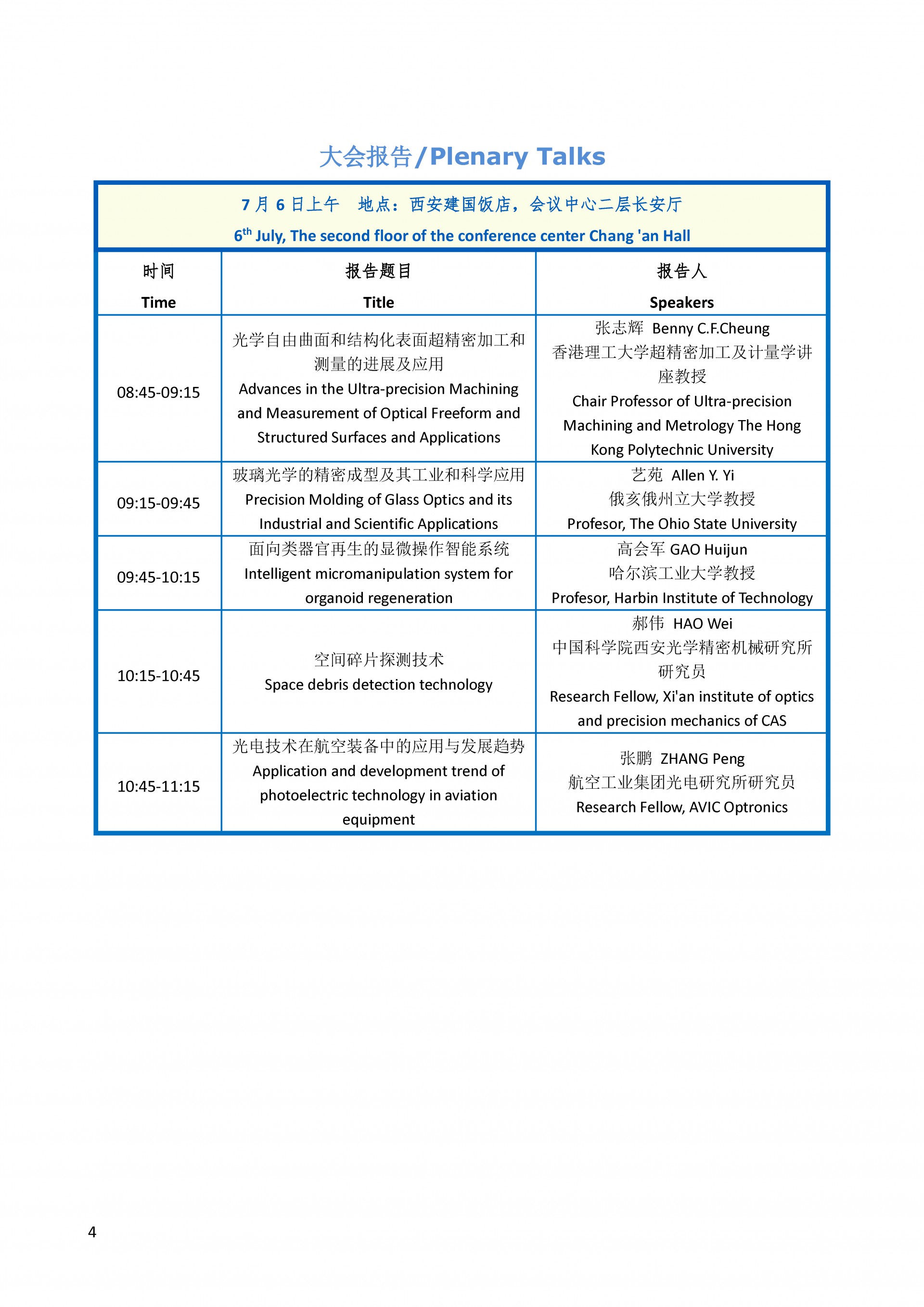

plenary talk:

Benny C.F. Cheung,香港理工大学——光学自由曲面和结构化表面超精密加工和测量的进展及应用

Allen Y. Yi ,The Ohio State University——Precision Molding of Glass Optics and its Industrial and Scientific Applications

高会军,哈尔滨工业大学——面向类器官再生的显微操作智能系统

郝伟,中国科学院西安光学精密机械研究所——空间碎片探测技术

张鹏,中国航空工业集团公司洛阳电光设备研究所——

张鹏,中国航空工业集团公司洛阳电光设备研究所——光电技术在航空军事装备中的应用与发展趋势

Sponsor:

Chinese Society for Optical Engineering (CSOE)

Organizers:

Xi'an Institute of Optics and Precision Mechanics of CAS

Xi’an Technological University

University of Shanghai for Science and Technology

Shanghai Engineering Research Center of Ultra-Precision Optical Manufacturing, Fudan University

Chinese Society of Optical Engineering Advanced Optical Manufacturing Youth Expert Committee

Co-organizers:

Beijing Space Electromechanical Research Institute

Xi 'an Institute of Applied Optics

Shenzhen Technology University

National defense science and technology industrial optical measuring station

Support Units:

Linding Optical (Shanghai) Co., Ltd.

MDPI (Wu Han)

Honorary Chairs:

ZHUANG Songlin, Academician, University of Shanghai for Scienceand Technology

ZHUANG Songlin, Academician, University of Shanghai for Scienceand Technology

JIANG Zhuangde, Academician, Xi’an Jiaotong University

JIANG Zhuangde, Academician, Xi’an Jiaotong University

Chairs:

GUO Dongming, Academician, Dalian University of Technology

GUO Dongming, Academician, Dalian University of Technology

TAN Jiubin, Academician, Harbin Institute of Technology

TAN Jiubin, Academician, Harbin Institute of Technology

ZHANG Xuejun, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

ZHANG Xuejun, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

Executive Chairs

LIU Weiguo, Xi`an Technological University

LIU Weiguo, Xi`an Technological University

HAO Wei, Xi'an Institute of Optics and Precision Mechanics of CAS

HAO Wei, Xi'an Institute of Optics and Precision Mechanics of CAS

WANG Xiaoyong, Beijing Institute of Space Mechanics & Electricity

WANG Xiaoyong, Beijing Institute of Space Mechanics & Electricity

DAI Yifan, National University of Defense Technology

DAI Yifan, National University of Defense Technology

Chairs of the Organizing Committee

ZHAO Jianke, Xi'an Institute of Optics and Precision Mechanics of CAS

ZHAO Jianke, Xi'an Institute of Optics and Precision Mechanics of CAS

ZHOU Shun, Xi’an Technological University

ZHOU Shun, Xi’an Technological University

Member of organizational committee

Chen,Wei-Jun,Carl Zeiss AG

ChenLiang-Chia,National Taiwan University

ChenShih Chi,The Chinese University of Hong Kong

Fengzhou Fang,Tianjin University

Huang Han,The University of Queensland

Kim Seung-woo,Korea Advanced Institute of Science and Technology

Daewook Kim,University of Arizona

Sandy To,The Hong Kong Polytechnic University

Lei Wei,Nanyang Technological University

Xichun Luo,University of Strathclyde

Kazuya Yamamura,Osaka University

Saulius Juodkazis,Swinburne University of Technology

YSAOM2024 Presidium:

l Chairs:

KONG Lingbao, Fudan University

KONG Lingbao, Fudan University

ZHANG Dawei, University of Shanghai for Science and Technology

ZHANG Dawei, University of Shanghai for Science and Technology

XU Liang, Xi'an Institute of Optics and Precision Mechanics of CAS

XU Liang, Xi'an Institute of Optics and Precision Mechanics of CAS

l Co-Chairs(Sort alphabetically by family name):

GAO Ping, Institute of Optics and Electronics, CAS

GAO Ping, Institute of Optics and Electronics, CAS

GUO Jiang, Dalian University of Technology

GUO Jiang, Dalian University of Technology

JI Shijun, Jilin University

JI Shijun, Jilin University

LIU Huasong, Tianjin Jinhang Institute of Technical

LIU Huasong, Tianjin Jinhang Institute of Technical

LI Ming, Xi'an Institute of Optics and Precision Mechanics of CAS

LI Ming, Xi'an Institute of Optics and Precision Mechanics of CAS

PENG Yunfeng, Xiamen University

PENG Yunfeng, Xiamen University

REN Mingjun, Shanghai Jiao Tong University

REN Mingjun, Shanghai Jiao Tong University

SUN Guoyan, Xi'an Institute of Optics and Precision Mechanics of CAS

SUN Guoyan, Xi'an Institute of Optics and Precision Mechanics of CAS

WANG Sujuan, Guangdong University of Technology

WANG Sujuan, Guangdong University of Technology

WANG Yonggang, Beijing Institute of Space Mechanics & Electricity

WANG Yonggang, Beijing Institute of Space Mechanics & Electricity

WEI Chaoyang, Shanghai Institute of Optics and Fine Mechanics, CAS

WEI Chaoyang, Shanghai Institute of Optics and Fine Mechanics, CAS

XUE Changxi, Changchun University of Science and Technology

XUE Changxi, Changchun University of Science and Technology

XUE Donglin, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

XUE Donglin, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

ZHANG Jiyou, Zhejiang Dali Technology Co., Ltd

ZHANG Jiyou, Zhejiang Dali Technology Co., Ltd

ZONG Wenjun, Harbin Institute of Technology

ZONG Wenjun, Harbin Institute of Technology

LIANG Haifeng, Xi’an Technological University

LIANG Haifeng, Xi’an Technological University

Micromachines合作特刊”Advanced Optical Manufacturing Technologies & Applications”,Scopus,SCIE (Web of Science), PubMed, PMC, EI Compendex,dblp 收录

Micromachines (ISSN 2072-666X) 是一个国际化、经同行评审的开放获取期刊,致力于为研究微/纳米级结构、材料、设备和系统等微纳科技基础研究到应用的学者提供一个交流平台。本特刊旨在收集本次优秀会议论文的扩展版本,欢迎各位老师投稿。

Micromachines Special issue on “Advanced Optical Manufacturing Technologies & Applications”,indexed within Scopus, SCIE (Web of Science), PubMed, PMC, Ei Compendex, dblp, and other databases.

Micromachines (ISSN 2072-666X) is an open access journal which provides an advanced forum for the science and technology of studies on micro/nano-scaled structures, materials, devices, systems as well as related micro- and nanotechnology from fundamental research to applications. This Special Issue will publish selected papers from the 2nd International Conference on Advanced Optical Manufacturing Technologies & Applications & 4th International Forum of Young Scientists on Advanced Optical Manufacturing (AOMTA & YSAOM 2024) in Micromachines. You are welcome to contribute to the Special Issue.

Papers published in the Special issue will receive a 15% (390 CHF) discount on article processing charge (APC).

网站:Advanced Optical Manufacturing Technologies and Applications

编辑部邮箱:micromachines@mdpi.com

联系人邮箱:aria.zeng@mdpi.com

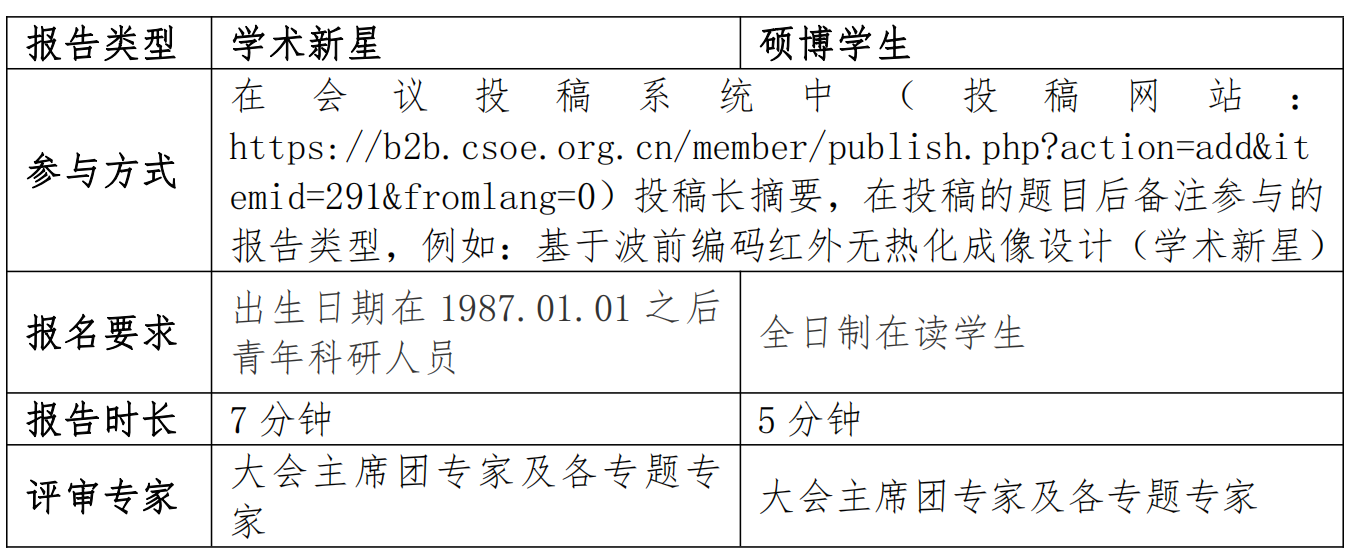

为进一步加强青年人才队伍建设,激发青年学者的科研热情,支持鼓励青年学者的成长,本次大会由大会主席团专家和各专题专家牵头,在会议期间组织两场青年学者报告专场并评出优秀报告授予证书,参与方式及相关信息参见下表,专场具体举办时间及安排将另行通知,欢迎广大青年学者积极投稿报名参与,截止时间为6月15日。

中国光学工程学会是中国民政部批准的全国性一级学会。学会以学术交流、工业展览、技术评估、项目转化、教育培训、融资对接、印刷出版、信息网络等多种形式,搭建产学研大平台,以培养助推光学工程年轻领军人才。学会官网:www.csoe.org.cn

当前,正值光电技术高速发展并得到广泛应用的时期,学会将充分利用独特资源,以丰富的活动,积极为广大会员搭建平台,相信您一定会在活动中有所收获!我们热诚欢迎您!

可点击链接https://www.csoe.org.cn/Site/Passport/signup.html,注册会员采集系统,点击“会员申请”,填写个人信息。

请您在采集系统“推荐人”这一栏填写活动名称“光学制造”,组委会将协助跟进后续审核等具体事宜。

附件0-中国光学工程学会简介.pdf

附件0-中国光学工程学会简介.pdf  附件1-中国光学工程学会会员管理办法.pdf

附件1-中国光学工程学会会员管理办法.pdf

附件2-中国光学工程学会会费收取和使用管理办法.pdf

附件2-中国光学工程学会会费收取和使用管理办法.pdf

!(填写姓名)青委会委员信息申请表.doc

!(填写姓名)青委会委员信息申请表.doc

Contacts:

Conference:

WANG Haiming(CSOE)

wanghaiming@csoe.org.cn,022-59013420

XU Liang (Xi'an Institute of Optics and Precision Mechanics of CAS)

xuliang@opt.ac.cn,17702907676

Submission and Registration:

REN Jie(CSOE)

renjie@csoe.org.cn,010-63726007

LI Yingchun(Changchun University of Technology)

liyingchun@ccut.edu.cn

SUN Guoyan (Xi'an Institute of Optics and Precision Mechanics of CAS)

sunguoyan@opt.ac.cn,18209230928

Industrialization Forum:

REN Jie(CSOE)

renjie@csoe.org.cn,010-63726007

LV Zichen(CSOE)

lvzichen@csoe.org.cn,13810226340

Sponsorship:

LV Zichen(CSOE)

lvzichen@csoe.org.cn,13810226340

Short courses and workshops:

REN Jie(CSOE)

renjie@csoe.org.cn,010-63726007

Experience Sharing session for Young Scholars:

REN Jie(CSOE)

renjie@csoe.org.cn,010-63726007

※第八届亚太光学制造会议暨第三届国际先进光学制造青年科学家会议

The 8th Asia Pacific Conference on Optics Manufacture & 3rd International Forum of Young Scientists on Advanced Optical Manufacturing(APCOM & YSAOM 2023)

https://b2b.csoe.org.cn/meeting/YSAOM2023.html

第八届亚太光学制造会议暨第三届国际先进光学制造青年科学家会议(APCOM & YSAOM 2023)顺利闭幕!

https://mp.weixin.qq.com/s/GOmwgyFnB8Qf_28WdwR1PQ

※ International Conference on Advanced Optical Manufacturing Technologies & Applications 2022 & 2nd International Forum of Young Scientists on Advanced Optical Manufacturing(AOMTA & YSAOM 2022)

https://b2b.csoe.org.cn/meeting/YSAOM2022.html

2022年先进光学制造技术及应用国际会议暨第二届国际先进光学制造青年科学家论坛(AOMTA & YSAOM 2022)顺利闭幕!

https://mp.weixin.qq.com/s/dkBnShO365gPd7FvTcWR4A

※" The 7th Asia Pacific Conference on Optics Manufacture(APCOM2021) & 2021 International Forum of Young Scientists on Advanced Optical Manufacturing(YSAOM2021)"

https://b2b.csoe.org.cn/meeting/YSAOM2021.html

Benny C.F. Cheung,香港理工大学——光学自由曲面和结构化表面超精密加工和测量的进展及应用

Benny C.F. Cheung,香港理工大学——光学自由曲面和结构化表面超精密加工和测量的进展及应用

Allen Y. Yi ,The Ohio State University——Precision Molding of Glass Optics and its Industrial and Scientific Applications

Allen Y. Yi ,The Ohio State University——Precision Molding of Glass Optics and its Industrial and Scientific Applications 高会军,哈尔滨工业大学——面向类器官再生的显微操作智能系统

高会军,哈尔滨工业大学——面向类器官再生的显微操作智能系统 郝伟,中国科学院西安光学精密机械研究所——空间碎片探测技术

郝伟,中国科学院西安光学精密机械研究所——空间碎片探测技术 张鹏,中国航空工业集团公司洛阳电光设备研究所——光电技术在航空军事装备中的应用与发展趋势

张鹏,中国航空工业集团公司洛阳电光设备研究所——光电技术在航空军事装备中的应用与发展趋势 ZHUANG Songlin, Academician, University of Shanghai for Scienceand Technology

ZHUANG Songlin, Academician, University of Shanghai for Scienceand Technology JIANG Zhuangde, Academician, Xi’an Jiaotong University

JIANG Zhuangde, Academician, Xi’an Jiaotong University GUO Dongming, Academician, Dalian University of Technology

GUO Dongming, Academician, Dalian University of Technology TAN Jiubin, Academician, Harbin Institute of Technology

TAN Jiubin, Academician, Harbin Institute of Technology ZHANG Xuejun, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

ZHANG Xuejun, Changchun Institute of Optics, Fine Mechanics and Physics, CAS LIU Weiguo, Xi`an Technological University

LIU Weiguo, Xi`an Technological University HAO Wei, Xi'an Institute of Optics and Precision Mechanics of CAS

HAO Wei, Xi'an Institute of Optics and Precision Mechanics of CAS WANG Xiaoyong, Beijing Institute of Space Mechanics & Electricity

WANG Xiaoyong, Beijing Institute of Space Mechanics & Electricity DAI Yifan, National University of Defense Technology

DAI Yifan, National University of Defense Technology ZHAO Jianke, Xi'an Institute of Optics and Precision Mechanics of CAS

ZHAO Jianke, Xi'an Institute of Optics and Precision Mechanics of CAS ZHOU Shun, Xi’an Technological University

ZHOU Shun, Xi’an Technological University KONG Lingbao, Fudan University

KONG Lingbao, Fudan University ZHANG Dawei, University of Shanghai for Science and Technology

ZHANG Dawei, University of Shanghai for Science and Technology XU Liang, Xi'an Institute of Optics and Precision Mechanics of CAS

XU Liang, Xi'an Institute of Optics and Precision Mechanics of CAS GAO Ping, Institute of Optics and Electronics, CAS

GAO Ping, Institute of Optics and Electronics, CAS GUO Jiang, Dalian University of Technology

GUO Jiang, Dalian University of Technology JI Shijun, Jilin University

JI Shijun, Jilin University LIU Huasong, Tianjin Jinhang Institute of Technical

LIU Huasong, Tianjin Jinhang Institute of Technical  LI Ming, Xi'an Institute of Optics and Precision Mechanics of CAS

LI Ming, Xi'an Institute of Optics and Precision Mechanics of CAS PENG Yunfeng, Xiamen University

PENG Yunfeng, Xiamen University REN Mingjun, Shanghai Jiao Tong University

REN Mingjun, Shanghai Jiao Tong University SUN Guoyan, Xi'an Institute of Optics and Precision Mechanics of CAS

SUN Guoyan, Xi'an Institute of Optics and Precision Mechanics of CAS WANG Sujuan, Guangdong University of Technology

WANG Sujuan, Guangdong University of Technology WANG Yonggang, Beijing Institute of Space Mechanics & Electricity

WANG Yonggang, Beijing Institute of Space Mechanics & Electricity WEI Chaoyang, Shanghai Institute of Optics and Fine Mechanics, CAS

WEI Chaoyang, Shanghai Institute of Optics and Fine Mechanics, CAS XUE Changxi, Changchun University of Science and Technology

XUE Changxi, Changchun University of Science and Technology  XUE Donglin, Changchun Institute of Optics, Fine Mechanics and Physics, CAS

XUE Donglin, Changchun Institute of Optics, Fine Mechanics and Physics, CAS ZHANG Jiyou, Zhejiang Dali Technology Co., Ltd

ZHANG Jiyou, Zhejiang Dali Technology Co., Ltd ZONG Wenjun, Harbin Institute of Technology

ZONG Wenjun, Harbin Institute of Technology LIANG Haifeng, Xi’an Technological University

LIANG Haifeng, Xi’an Technological University